Custom-tailored pump solutions for various industries.

Pumping solutions that make efficient use of fibers and energy

Integrated pumps concept by ANDRITZ for PM2 at Zellstoff Pöls AG

ANDRITZ was awarded the contract to supply all of the process pumps for the new PM2 kraft paper machine at Zellstoff Pöls AG, Austria. Stock pumps from the new ACP process pumps series were installed for this project. The project demonstrated the efficiency of the new ACP process pumps series.

After a record construction period of just over 13 months, the Heinzel Group's PM2 at Zellstoff Pöls AG, Austria, went into operation in November 2013. It is the largest and most advanced kraft paper machine in Europe. ANDRITZ had received the order to supply a PrimeLine plant for production of specialty papers. The scope of supply included the stock preparation plant, an approach flow system, the complete Fourdrinier paper machine, a high-precision drying cylinder, and the automation systems. ANDRITZ also supplied all of the process pumps for the new production plant. The 115 million euro investment increased the paper production capacity at the facility to 80,000 tons per year. The very high-quality bleached kraft paper is known under the brand name of Starkraft. It was no coincidence that the symbol chosen was a flying rhino – symbolizing both strength and flexibility. The kraft papers market segment is a highly specialized market with the highest quality standards. Integrated production at the Pöls location not only ensures a continuous supply of raw material for the paper machine, but also contributes towards energy-efficient production.

Zellstoff Pöls AG

High-performance pulp production and stock preparation

The Zellstoffwerk Pöls pulp mill is currently able to produce 430,000 t/a and is the largest producer of bleached ECF long-fiber sulfate pulp in Central and Southeastern Europe. Every year, two million cubic meters of wood are processed, primarily in CO2-neutral operations. The PM2 has two stock preparation lines. The first of them feeds long-fiber sulfate pulp produced at the mill to the paper machine, while the second stock preparation line supplies short-fiber pulp to the pulp cycle. This guarantees the optimum composition of raw materials for the demanding kraft paper production process.

The entire paper-making equipment is distributed over three levels: The pumps and the two stock preparation lines are installed on level one. The complete paper machine with finishing equipment and control room are on level two. In the side aisle of the paper machine building, the entire air system for the new plant is located on level three.

Pumps delivery program for PM2 in Pöls

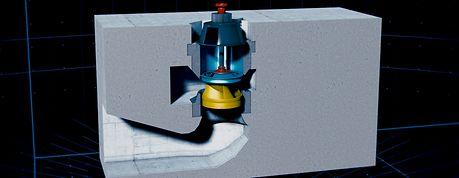

ANDRITZ supplied all of the process pumps for the new PM2 kraft paper machine at Zellstoff Pöls AG. The scope of supplies and services comprises the engineering work and supply of 30 stock pumps from the new ACP process pumps series, six water pumps from the ISO series, two 'S' series stock and water pumps, two high-pressure pumps from the MP series, and two FP series double-suction fan pumps.

Stock and water pumps from the ‘S’ series operating at Zellstoff Pöls AG

Operating reliability and cost-efficiency

In addition to the supply of top-class equipment, professional and appropriate installation of the components guarantees trouble-free start-up and reliable plant operations in the long term. ANDRITZ specialists carried out the installation of the PM2 in Pöls, including the required precision alignment of the components, in close cooperation with the future operating personnel. Thus, it was possible to provide intensive training for future equipment operators and in-depth knowledge of the specific technical context.