The world´s most comprehensive portfolio of separation technologies.

Filter press: After sales, spare & wear parts, repairs, etc.

Your full-service provider

Whether you need spare parts, local service, repairs, overhauls, or modernization of your filter press, ANDRITZ SEPARATION – as the OEM behind Rittershaus & Blecher and Netzsch Filtration – is your full-service provider when it comes to overhead and sidebar filter presses with different filter element technologies like chamber filter presses, membrane filter presses, as well as plate and frame filter presses.

Request a quote

Find your service center here!

High-quality filter cloths

- Up to 20% longer service life & more solid content in the cake

- Easy cake release due to super smooth surface finish on the cloth

- 150 years of experience in solid/liquid separation processes guarantees you to get the right filter cloths for your specific application and needs

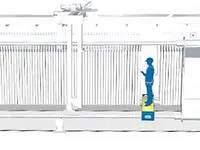

SmartFEED: Exchange the filter cloth in your filter press with up to 40% less downtime

Suitable for any model and make of sidebar and mining filter presses with an external top feed port

40% less downtime thanks to faster replacement of filter cloths

- Lower operating costs due to re-usable feed shoe

- Easy to retrofit

SmartLIFT lifting device for overhead filter presses

- This hydraulic lifting system is suitable for all models and makes of overhead filter presses

- SmartLIFT reduces downtime by up to 40%

- Easier, safe, and faster exchange of filter cloths

- Increased production time

- Simple for the operator to control (no need for assistance from a second operator)

- Rechargeable battery included for plate sizes 1500x2000 and 2000x2000

Complete repair of filter presses

- Repair of the filter press frame

- Replacement of wear parts

Upgrades or replacements of devices

- Drip trays

- Washing cloths device single and washing cloths device multiple

- Auxiliary cake discharge

- Cloth washing system

Optimization and upgrades for automation

- Fully automatic filtration process

- Complete control of components (pumps, air, compressor, valves, e.g.)

- Repairs and upgrades of electrical panel

- Electrical spare parts

- Implementation of safety electrical components

Standard spare kits are available for

- Closing system device

- Hydraulic unit

- Shift plate device

- Filter cloths

- Filter plates

- Load cells