BREAKING AWAY FROM THE NORM

The Institute of Innovation Management at TU Graz in Austria breaks away from the norm at universities and complements industrial operations by delivering a combination of traditional, high-quality education mixed with real, practical industry cases.

Professor Christian Ramsauer, Head of the institute in Graz, is himself a former CEO of a high-tech company and joined TU Graz in 2011. “When I joined the institute, it was to focus on teaching and stressing the importance of creative innovation in industry,” says Ramsauer. “Most importantly, I wanted to ensure that the technical university was a partner of industry so that students could benefit from the real-life challenges that are presented in all types of manufacturing.”

As part of this engagement with industry, the university introduced a dedicated, unique course inspired by the one-year program in Design Thinking offered by the Stanford University in California, USA. In the case of TU Graz, the course was named “Product Innovation” which is based on the concept of Experience Based Learning, giving students the opportunity to work on real-life tasks directly provided by industry partners, such as ANDRITZ.

AMAZING WHAT STUDENTS CAN DO

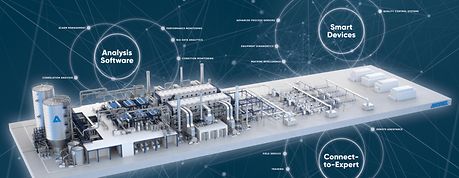

ANDRITZ management spotted the opportunity the institute offers with its Product Innovation course early on and has been a partner with the university several times over the last years. The collaboration involves ways to maximize the performance of its technology in its many different fields of industry.

Ramsauer said, “Austrian companies such as ANDRITZ have a real opportunity when they work with us by having access to very enthusiastic, well-educated students who are unencumbered with corporate rules or boundaries and can really think in a creative way on the solutions to challenges.

“We always find it amazing what students can do when they are working in diverse teams, from different backgrounds.”

Marion Unegg, Project Leader of the Project Innovation courses has a background in environmental system sciences and economics, and is now in her fourth year as project leader at the university. Unegg says, “The latest challenge sent to us by ANDRITZ was to find ways to make the pulp drying process more energy efficient and contribute to making the pulp mill more circular when it comes to sustainability and carbon footprint reduction.”

THE CHALLENGE FROM ANDRITZ

After the team was formed and consolidated, the challenge posed to the Product Innovation team came direct from ANDRITZ. Sebastian Harringer, student Team Leader for the challenge, said, “The project concerned the reusing of energy in the drying area of a pulp mill. The specific challenge was to reuse two exhaust streams from the dryer in the most feasible way possible.”

As the task began, more details from ANDRITZ were included, as well as some overall restrictions and limitations. There was also a mill visit to a pulp mill near Graz. “The mill visit was the perfect place to begin,” says Harringer. “We were all very impressed with the size of the dryer, and of course with the pulp mill itself. We were very enthused by what we saw, and it helped greatly to come up with ideas for a solution.”

The whole project on the ANDRITZ challenge took place over a period of seven months with regular check points in between to monitor progress.