ANDRITZ offers rebuilds, spare parts, upgrades, and on-site services for refiner equipment from virtually any OEM.

Savonlinna refiner test bench - A powerful service for all refiners

Twenty years ago ANDRITZ rebuilt the first competitor refiner at its Savonlinna site in Finland. Since then a huge amount of development has taken place and now the refiner service division is truly global in its scope. The division offers service and maintenance of several kinds and types of refiners independent of the OEM.

The Savonlinna site is located northeast of Helsinki, in Finland and has quickly evolved as a dedicated, high-performance service center for almost every refiner operating globally in mechanical pulping and MDF industries. Historically, there has always been a lot of experience in pulp service knowhow on the site; the workshops were first built over 100 years ago and were formerly owned by pulp and paper giant Stora Enso, followed by Ahlstrom, before finally being taken over by ANDRITZ at the beginning of 2000.

SERVICE FOR ALL REFINER DESIGNS

ANDRITZ focuses on servicing and maintaining refiners for the pulping processes across the mill including chip washing, impregnation, HC refining, MC bleaching, and steam handling. As well as Savonlinna – ANDRITZ’s main site for competitor refiners – there are also four other service hubs specialized in refiners located in Graz, Austria; Brantford in North America; Schuler in Brazil; and Foshan in China.

“In just a short space of time we have shared our global knowledge between all our service centers,” says Thomas Kaiser, Director, HC-Refiner Service, ANDRITZ. “The ANDRITZ refiner service has now evolved very quickly from a predominantly spare parts supplier in the mid 2000s to a fully-fledged service offering with a very strong focus on engineering.” says Thomas Kaiser.

“Our real strength when it comes to servicing refiners is that we analyze each machine in detail; for instance, we have a calculation of the bearing lifetime based on the operational mode of the refiner We use these measurements along with a deep understanding of the refiner designs based on the refiner families manufactured by ANDRITZ (Sprout, Bauer, Hymac, Pilão, Enso) but also the knowledge we have gleaned from the non-OEMs.”

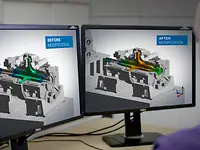

Alignment in ANDRITZ Test Bench

This combination of selecting the best features out of each design has led to multiple different upgrades: for example, the hydrodynamic thrust bearing for RGP refiners that allows higher production while extending the lifetime.

After the upgrade has taken place, each refiner goes through a rigorous test on specially developed test benches to ensure they are operating at the highest quality and efficiency.

“The test benches are a vital addition to our service offering with each refiner undergoing an average of eight hours of heavy testing before they are sent back to the customer,” adds Kaiser.

The latest update of the test benches has seen the testing area now completely enclosed inside a noise cancelling room for a safer working environment. Future upgrades will include an integrated online refiner protection and condition monitoring system, the ANDRITZ AdvaCon.

Like our company vision claim ‘The world keeps changing, our passion stays the same’, “We are ever curious, and ready for whatever comes next in the world of refiner maintenance and service,” concludes Kaiser.

Test Bench in action