“Operating hydropower stations in a way that is both sustainable and profitable is one of our core topics.”

Peter Gnos

Vice President of Market Management & Project Development for Latin America at ANDRITZ Hydro

Peter Gnos

Vice President of Market Management & Project Development for Latin America at ANDRITZ Hydro

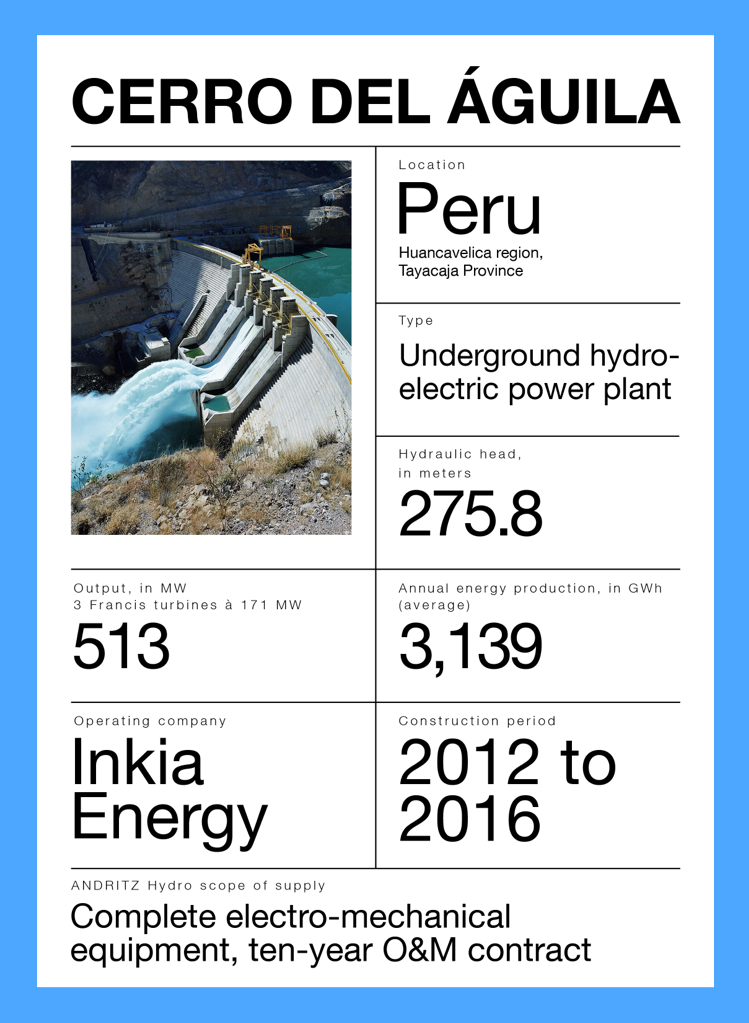

At over 1,500 meters above sea level amid the Peruvian Andes lies the country’s second-largest hydropower station, Cerro del Águila. On the “Eagles’ Hill” directly on the lower reaches of the Mantaro River, an average of 3,200 gigawatt hours of clean energy from hydropower have been generated annually and fed into the Peruvian grid since 2016. This corresponds to the energy requirement for 2.5 million Peruvian households. ANDRITZ supplied and installed the complete electro-mechanical equipment, including three large Francis turbines with an output of 171 megawatts each. But that was only the beginning.

Dam at the Cerro del Águila hydropower plant

After commissioning, close cooperation was established with the power plant operator, Inkia Energy. The two companies concluded a ten-year service agreement to operate the hydropower plant as flexibly and economically as possible – with close communication between the two parties. At the core is Metris DiOMera – the digital platform developed by ANDRITZ that enables hydropower stations to be monitored remotely, controlling their output to achieve the given targets and planning their maintenance work accurately.

“Metris DiOMera is based on a large amount of data collected constantly during the power plant’s ongoing operations and from its surroundings,” says Peter Gnos, Vice President of Market Management & Project Development for Latin America at ANDRITZ Hydro. This data includes the water level of the Mantaro River, the proportion and density of sand and sediments in the water, but also the oil temperature and oil pressure in the power station’s hydraulic units, vibration of the machines and temperature of the cooling water.

Frank Sugrañes

Chief Technical Officer, Inkia Energy

All of this information is collected in Cerro del Águila, sent via secure online communication to the ANDRITZ Hydro Global Control Center in Schio, Northern Italy, and analyzed there on the basis of sophisticated mathematical models and algorithms by ANDRITZ experts with decades of experience. “For example, unusual changes in output, vibration or temperature indicate very quickly that the hydropower plant is not being controlled to optimum benefit or that problems are emerging. Based on these facts and our forecasts, we then advise our colleagues at Inkia Energy and suggest various courses of action,” says Peter Gnos. Furthermore, and this is particularly helpful for the operator, Metris DiOMera then becomes an important tool to make well-founded predictions of future output and expected wear on basic components, such as bearings, runners or generators.

This approach convinced Inkia Energy. “Working together with ANDRITZ, we share the responsibility for achieving the best possible operating conditions in the hydropower plant,” says Frank Sugrañes, the energy provider’s Chief Technical Officer. “ANDRITZ guarantees us that the plant achieves the best possible performance under previously defined conditions. The actual operating hours form the basis, enabling us to distribute the maintenance budget to optimum advantage in the long term.” Planning and execution of maintenance work become more flexible and more effective, Frank Sugrañes explains: “As the ANDRITZ experts and our personnel carry out this work together, we obtain a high level of reliability, availability and performance by the hydropower plant.”

An agile maintenance model has taken shape in Cerro del Águila that considers a multitude of variables – even the current market prices for electricity – in order to determine the optimum time to repair or replace components. The focus lies on transparency and economic efficiency. For example, thanks to digital networking of Metris DiOMera, the efficiency of each turbine can be retrieved in real time and its life span can be predicted reliably. “Thanks to our many years of experience from projects all around the world and our digital tools, ANDRITZ has profound expertise to actively advise its customers,” says Peter Gnos. “Operating hydropower stations in a way that is both sustainable and profitable is one of our core topics.”

The fact that the focus lies more than ever on flexible use is also displayed by the way in which Cerro del Águila deals with spare parts management. ANDRITZ puts together packages of small, but important spare parts for the customer, such as filters, seals or circuit boards. These are kept in stock at the plant, inventoried once a year and restocked if necessary. Hence, the local team is well equipped to conduct immediate, minor repairs. “This way, we avoid long delivery times, can fix problems directly and avert production downtimes,” says Frank Sugrañes. “We have good and trusting cooperation with ANDRITZ, so we are considering implementing further improvements at the plant. In the end, it is the mutual benefit that counts.”