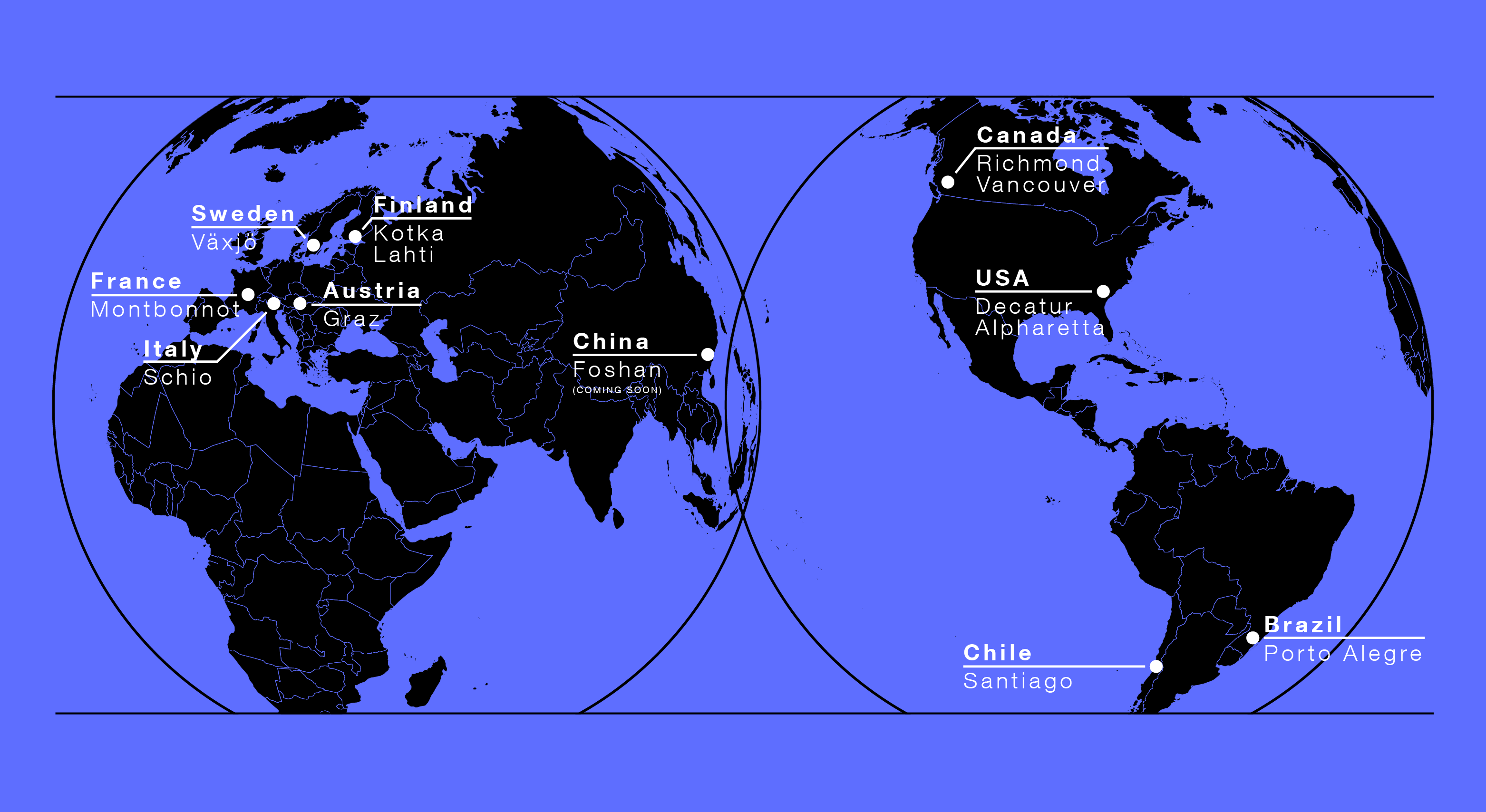

Worldwide presence

ANDRITZ’s Metris Performance Centers have proved to be a strong partner in large industrial projects all over the world: In China, for example, they helped start up a new wastewater treatment plant and several paper machines remotely. Remote support was provided in starting up two biomass boilers in Japan, in ramping up a fiberline in Spain, and in starting up filter presses in the USA.

“In the start-up phase in particular, networking the digital with the physical world of industry has enormous advantages,” says Gerhard Schiefer, Chief Automation Officer at ANDRITZ. “We have process engineers, automation experts and mechanics working together in a multidisciplinary team – to the greatest possible benefit of the customer.”

The experts provide active assistance during start-up of the plant and contribute their specific knowledge. In collaboration with small teams on site, this enables a quick start-up, and other tasks can also be performed with the aid of digitalization.