"ENVIRONMENTAL PROTECTION AND SUSTAINABLE DEVELOPMENT ALWAYS PLAY AN IMPORTANT ROLE IN OUR PRODUCTION."

Yu-Lon Chiao,

Chairman of Walsin Lihwa

WATER IS A PRECIOUS COMMODITY

that is consumed by more and more people worldwide. In terms of sustainability, however, it is not only direct water consumption that is important. The water needed for the production of food and industrial goods is also playing an increasingly important role.

99% LESS NITRATE

The Taiwanese company Walsin Lihwa uses ANDRITZ technology to set new standards in dealing with acids and water in the production of stainless steel. The waste pickling acid from the production process is treated, and up to 99% of the nitrate can be filtered out of the water. A closed loop is formed, and water consumption drops significantly.

Precious commodity: Taiwan has a shortage of fresh water.

© Getty ImagesYu-Lon Chiao,

Chairman of Walsin Lihwa

Water is also an important topic for Walsin Lihwa. The Taiwanese Group established in 1966 is one of Greater China’s leading producers of wire and cables, stainless steel, and commodities, and is also active in real estate. Its products are used in many infrastructure projects. Walsin Lihwa’s annual revenue is over 130 billion New Taiwan dollars (around 4.17 billion euros), and the company has around 5,000 employees.

“Environmental protection and sustainable development always play an important role in our production operations,” says Chairman Yu-Lon Chiao. “In order to combat climate change and the increasing shortage of natural resources, we have invested heavily in saving energy, reducing CO2 emissions and recycling valuable resources in recent years.”

According to the World Resources Institute, the amount of ground water extracted worldwide since the 1960s has more than doubled. 44 countries are suffering from a precarious water supply. Many countries are threatened with acute shortages and a permanently short supply if there is too little precipitation or a long heat wave.

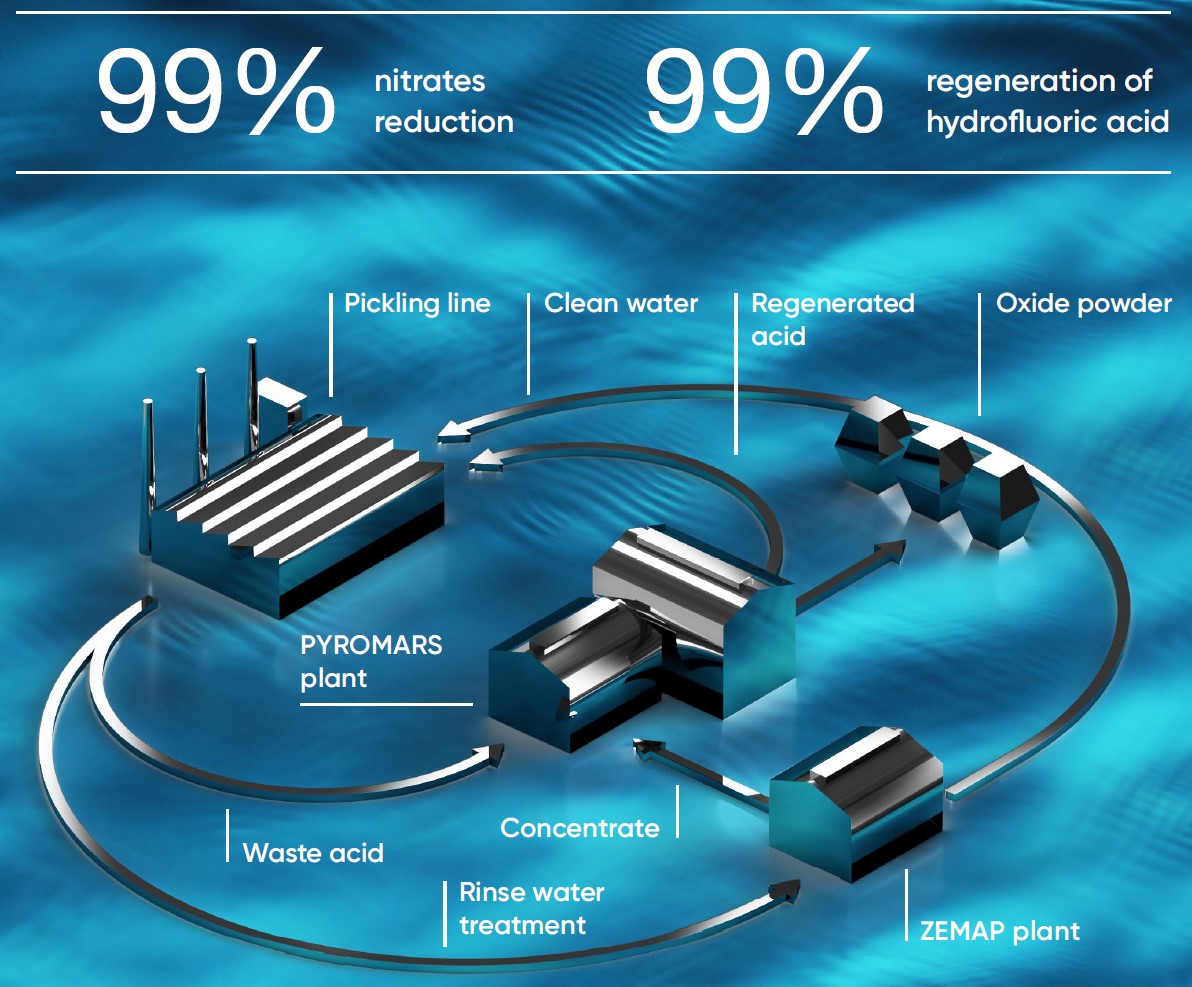

Two ANDRITZ systems – PYROMARS and ZEMAP – that the company uses in central process stages of its steel production plant are examples of these activities. After the steel has been hot-rolled and annealed, any residues must be removed from the surface. A mixture of nitric and hydrofluoric acid is used as the pickling agent, which is rinsed off afterwards. “PYROMARS regenerates the hydrofluoric acid and thus completely closes this loop, substantially reducing the amount of nitrate in the wastewater and the sludge volume after wastewater treatment. What remains is the mixed acid pollutant in the rinsing water,” says Arthur Stingl, Senior Vice President of ANDRITZ Metals. “Thanks to ZEMAP, this contaminant can also be treated.”

The outcome: Water consumption is reduced, overall consumption of fresh hydrofluoric acid is close to zero, and the sludge volume remaining after treating the mixed acid wastewater – and which has to be disposed of – is falling rapidly. “Pickling, rinsing, and also recovery of the acids and the water become one closed loop thanks to these two plants,” Arthur Stingl adds. An innovation that aroused the experts’ attention: In 2018, ANDRITZ received the prestigious Energy Globe Award for developing PYROMARS and ZEMAP.

Two plants with one goal: acids and water in a closed loop

Valuable resource: The volume of ground water consumed has more than doubled worldwide since the 1960ies, according to the “World Resources Institute.”

© Artem Militonían on Unsplash / Plant Photo: ANDRITZIn practice, the plants have several advantages for Walsin Lihwa, including less sewage sludge, less fresh acid added to the pickling process, and more wastewater recycling. “For Walsin, the investment in environmental protection is not only necessary but also worthwhile in many respects. Walsin Lihwa will be concentrating on several topics in the future as well, for example reducing greenhouse gas and nitrogen oxide emissions or increasing the waste recycling quota,” adds Yu-Lon Chiao.

Steel is a pillar of the modern world. Without this material, architecture, car manufacturing, mechanical engineering, or the production of household goods and appliances would barely be conceivable. In 2020, around 50.9 million tons of stainless and heat-resistant raw steel were produced worldwide. (Source: International Stainless Steel Forum)

With the aid of the PYROMARS technology, the hydrofluoric and nitric acids used in stainless steel production are recovered and used again in the same production process. With the ZEMAP technology, the wastewater from the rinsing section can be treated and subsequently regenerated. Then the acidic concentrate from the ZEMAP plant is treated in the PYROMARS plant, and the cleaned water is used once again to rinse the steel.