ANDRITZ S.A. de C.V.

Av. Francisco Madero Ote. No. 5595

58200 Morelia, Michoacán

Mexico

This can been achieved by covering various process steps in the value chain (planning, key component manufacturing, in-house assembly, shipping, site erection, service support). The committed employees in research and development are working constantly to improve and enhance technologies and products.

ANDRITZ’s scope of products is therewith divided into mechanical and electrical which include, Francis, Pelton and Kaplan Turbines, Spherical and Butterfly Valves, Generators, Turbine Governors, Excitation Systems, Control, Protection and SCADA systems – up to services such as site installation, commissioning, and training with special focus on small services and all spare parts.

Francis Runners

Pelton Runners

Kaplan Runners

Valves

Welded Components

SERVICES

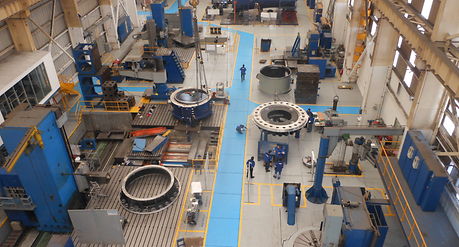

Manufacturing of hydro turbines and runners in Morelia

Turbine Governors

Excitation System

Controls System

Protection Systems

Electrical Power Systems (EPS)

We are certified by: