Dagachhu - Handover and project closing in Bhutan

HIPASE platform - First experiences with the new device

ANDRITZ HYDRO automation is the global leader for secondary equipment for hydropower plants as well as a supplier of excitation, protection, and synchronization systems for thermal power plants.

With the development of the new HIPASE platform, ANDRITZ HYDRO automation is actively reacting to a changing market environment for secondary systems (see Hydro News 24).

HIPASE – The new development

The main drivers for the new development are based primarily on new requirements for cyber security, homogeneous interfaces for all subsystems, simple and easy engineering, as well as a common platform for all functions.

Major goals of the development were the conflation of all different disciplines into one common platform, one common engineering workflow, as well as one common workflow for commissioning. HIPASE contains the following features in one unique platform:

- HIPASE-P (Electrical protection system)

- HIPASE-E (Excitation system, automatic voltage regulator – AVR)

- HIPASE-S (Synchronizing functionality)

- HIPASE-T (Turbine governing system)

Furthermore, by using one platform for all subsystems the training of engineers will be reduced to a minimum.

HIPASE – The approach to an unique platform

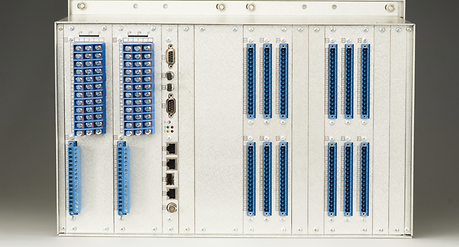

The HIPASE device consists of a half size 19” housing incorporating up to 32 digital inputs and outputs as well as 12 current and eight voltage transformer inputs. For all applications with extensive signal requirements (e.g. six winding transformer differential protection), a standard 19” full size housing can be used. All HIPASE devices usually contain four boards, individually combined according to the type of application. The processor board is the core component, also supporting different standard communication interfaces (e.g. IEC 61850 and IEC 60870-5-104). For processing of analogue and digital signals, appropriate analogue and digital interface boards are provided. HIPASE ensures the protection of humans and property as well as data integrity by both hardware and software measurement.

HIPASE device

HIPASE – Security

Due to the complex interconnection of the overall electrical energy generation and distribution infrastructure, cyber security has become increasingly important. This fact becomes clear in the related policies of key power utilities (e.g. the White Paper from Germany’s BDEW and the North American NERC CIP Standard).

Comprehensive and consistent security architecture protects the HIPASE device against cyber-attacks – exogenous as well as from the internal network. Core elements of this protection are an internal firewall as well as encrypted data transmission (communication between HIPASE engineering tool and HIPASE devices). Every HIPASE device is equipped with a trusted platform module (TPM) chip, clearly identifying each device and providing unique keys for authentication.

HIPASE – Engineering and touch panel operation

The HIPASE engineering tool is the perfect tool for easy and efficient engineering of the platform. It is used for all applications, such as excitation, protection, synchronization and turbine governor solutions. It has a future-oriented user interface and, in combination with the workflow-oriented menu structure, offers a new quality of user-friendliness.

The HIPASE engineering tool fits perfectly to user requirements and demands. All engineering steps of a project – parameterization, system test, commissioning, system monitoring, and maintenance – are supported by using the tool.

All applications are created with the help of the IEC 61131-3 function block diagram with a full graphic representation. In case of dedicated predefined functionality (e.g. ANSI protection functions) an engineering wizard will help to select the right functions without the need to create them by oneself.

The fully graphical touch panel allows the online visualization of process signals as well as an indication of internal process data. It is used for the complete operation of the HIPASE device.

Rosenheim hydropower plant

HIPASE – pilot projects in operation

ANDRITZ HYDRO automation has been awarded a lot of projects where HIPASE is used for various functions.

In Austria the first excitation HIPASE-E and protection system HIPASE-P have been installed and commissioned at the Ternberg run-of-river power plant on the Enns River. Two excitation systems have been delivered for two generators with an output of 25 MVA each. The protection system is designed to have complete redundancy with the use of two HIPASE devices for the generator and block protection for each unit.

On the river Inn in Germany HPP Rosenheim and HPP Feldkirch (both equipped with three 35 MW Kaplan units) and HPP Gars, HPP Wasserburg and HPP Teufelsbruck (equipped with five 25 MW Kaplan units) will be equipped with HIPASE-E excitation systems. For this project both types of application – excitation for rotating exciter units and static excitation systems – will be applied.

In Canada ANDRITZ HYDRO has received a contract for the delivery of excitation systems for five 18 MW units at HPP Shawinigan on the river Saint-Maurice, the first HIPASE excitation project in Canada. Recently, the first unit was delivered to the customer, after the test runs were successfully finished.

Furthermore, ANDRITZ HYDRO has been awarded a contract to supply a HIPASE-P protection system for HPP Nant de Drance. The newly-built pump storage power plant in Switzerland consists of six 174 MVA pump turbines (motor-generators). ANDRITZ HYDRO will equip all six motor-generators, six block transformers, and three station service transformers with HIPASE-P platforms. For all units the protection system will be designed with full redundancy.

HIPASE – future of automation

With the new HIPASE platform ANDRITZ HYDRO has developed the basis for future market requirements. Especially with the newest extension for turbine governor applications HIPASE can now be used for all dedicated tasks in hydropower plants. The unique hardware and engineering tool approach for all types of functionalities is the main advantage of the integrated platform. ANDRITZ HYDRO is looking forward to sharing its long-term experience in the field of secondary equipment with its customers.