How do you control industrial plants and entire factories or mills very efficiently?

How can we help lightweight carbon construction to gain acceptance in the automotive industry?

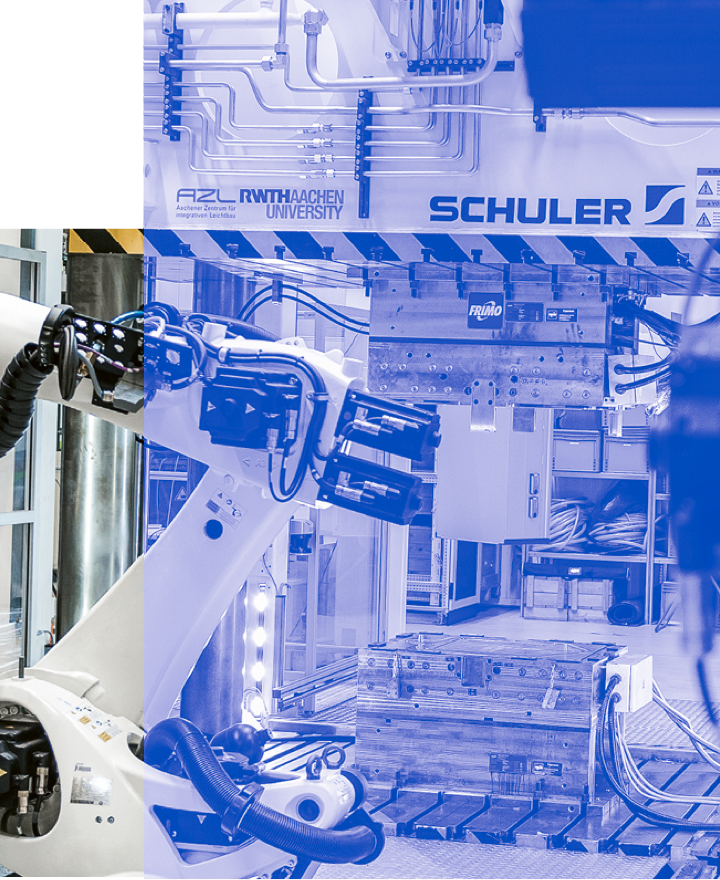

Lightweight fiber composites like carbon are promising candidates for large-scale production in car manufacturing. With the “iComposite 4.0” research project, the Lightweight Construction Center in Aachen, Germany, (Aachener Zentrum für Leichtbau – AZL) has made remarkable progress in terms of economic efficiency. Schuler – a member of the ANDRITZ GROUP and the globally leading supplier of cutting-edge technologies in all fields of metal forming – had the role of consortium leader here.

The AZL managing directors, Michael Emonts and Kai Fischer, explain the background to the project:

“The overall goal of our projects at AZL is to help companies save resources and costs and to make production of components faster and cheaper. With the iComposite 4.0 research program funded by the German Federal Ministry of Education and Research, we have been very successful in achieving this goal. As the consortium leader, effectively coordinating the work of the eight companies and two research institutes taking part, Schuler has contributed extensive know-how and a state-of-the-art press.

Dr. Kai Fischer (left) and Dr. Michael Emonts (right), managing directors of AZL

With iComposite 4.0, we have taken a big step forward in making the manufacture of parts from composites like carbon fiber reinforced plastic (CFRP) affordable, particularly for large-scale vehicle production. Taking the underbody panel of a British sports car as an example, cost-cutting potential of more than half and a reduction in lead time from 73 to 46 minutes have been forecast. In conventional car manufacturing, these parts cost almost 400 euros each, but with iComposite 4.0 only around 150 euros.

The clever thing about the newly developed modular production system is that it is fully automatic, it controls and makes adjustments largely independently, and it does not waste any material. So far, the producers of fiber-composite components have used carbon fiber mats that have to be cut to size as their raw material. As with a sheet of paper that is used to cut out a shape, a lot of the material is left over. Depending on the component concerned, up to 50 percent of the expensive carbon fibers cannot be used in this form and end up in the recycling.

With iComposite 4.0, the CFRP needed is all used up and there are no waste cuttings. In order to produce the composite-fiber mat, a robot only sprays on the basic structure of the fiber-glass component in the first step. Then the material distribution is checked visually using a 3D measuring system, and an algorithm calculates the individual rigidity of the component. In a separate stage, another robot lays out the carbon fibers with precision fit to reinforce the component.

The measuring data are also important in the next process step. Here, the resinated component is cured and molded in a hydraulic Schuler press. If, for example, visual surveying has detected that there are fewer fibers, the quantity of resin required can be adjusted. The press is able to specifically influence the deflection of the tool used inside the press. Thanks to the adaptivity of the production system, the waste produced as a result of variations in the fiber architecture can be eliminated.”

The state-of-the-art hydraulic upstroke short-stroke press from Schuler is ideally suited for fabrication of composites because it can provide its full pressing force after only a few fractions of a second. The parallelism control in combination with dynamic die adjustment ensures that the plastic is distributed to the optimum throughout the die. This reduces waste to a minimum.