YOUR BENEFITS

- Ultrasonic welding technology is skin-friendly thanks to the chemical-free process that minimizes allergic reactions and skin irritation

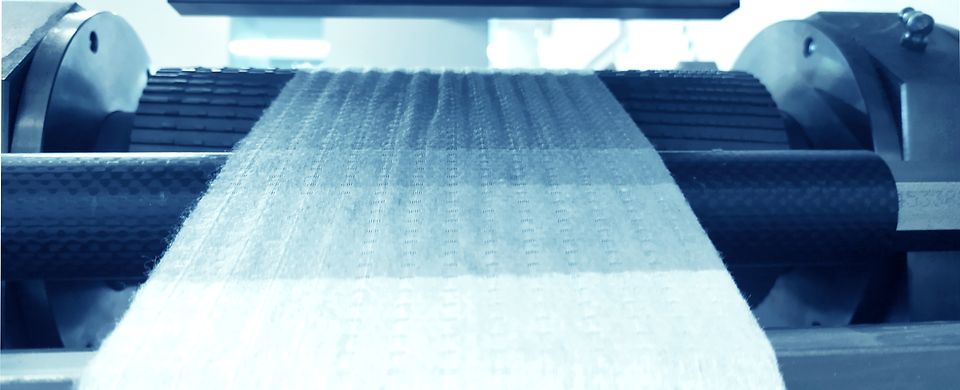

- Maximum fabric softness and elastic performance

- Cleaner production process and hence, reduced machine downtime

- Products manufactured with ultrasonic technology can be recycled more easily as they are made of recyclable materials

- Eco-friendly and less energy-consuming process