ANDRITZ Kaiser GmbH

Germany

Conventional automatic stamping presses and servo presses from 630 kN up to 25,000 kN

A large number of factors have to be taken into account when deciding on the right press: technical requirements from the product, expected productivity, technical requirements on the press line, integration into the existing production lines, fixed and running costs, process control, fast availability of maintenance/service, availability of spare parts – all these considerations influence mainly the total cost of ownership.

All presses are available with standard technical data or as customized applications.

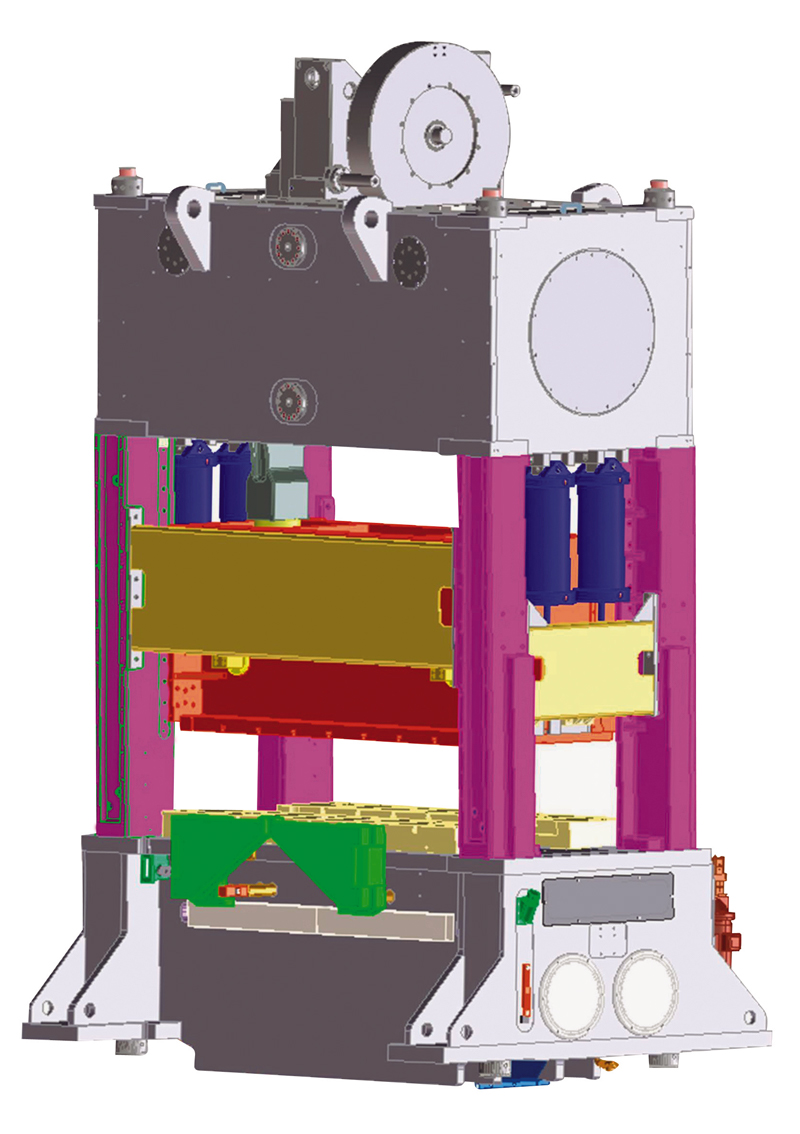

3,150 kN press with central gear box

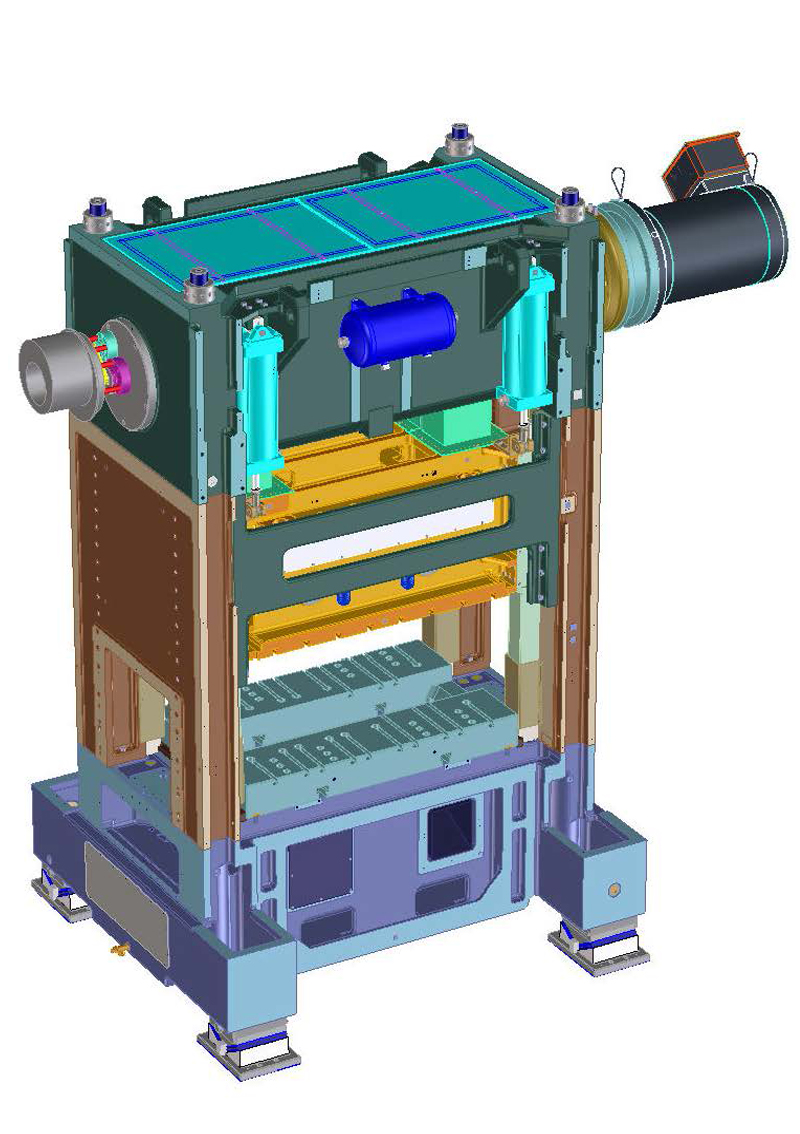

2,000 kN servo press with cast iron frame

Up to a press size of 6300 kN, all machines can be delivered in a split cast iron construction. Alternatively, the delivery takes place in a combined construction cast iron / welded steel machine main frame parts. Large presses are made exclusively from welded steel machine main frame parts. Welded components are manufactured by certified companies based on the ANDRITZ Kaiser welding guidelines. All welded components are heat treated before processing.