Issues in plastic production

❌ Made from fossil fuels

❌ High water and energy consumption

❌ Not biodegradable

❌ Often incinerated or land filled

❌ Breaks down into microplastics

❌ Harms marine life and ecosystems

❌ Under restrictions in Europe

Pulp is a natural material made from wood fibers. It is biodegradable, renewable, and available in large quantities, making it one of the most promising alternatives to plastics.

While pulp has traditionally been used in paper production, it is also becoming a key component in sustainable materials across various industries.

In the Nonwoven and Textile industry, pulp is already being used to create innovative, sustainable solutions. ANDRITZ enables the production of high-performance nonwoven materials used in hygiene, wipes, durable, automotive, medical, packaging and other applications. These solutions combine the natural benefits of pulp with industrial scalability—paving the way for more responsible single-use products.

As environmental regulations tighten and demand for eco-friendly solutions grows, pulp-based nonwovens are gaining interest. They offer a greener alternative to synthetic materials, are compostable, and can be produced efficiently at scale.

Traditional fiber-forming methods often rely on large amounts of water to shape and bind the material, which is why the process is called wetmolding . This not only increases energy consumption, for example in the drying process, but also limits production speed and scalability.

Dry Molded Fibers offer a different approach. It transforms pulp into strong items, using a process that is almost completely dry.

This means significantly lower water usage, faster cycle times, and a cleaner, more efficient production environment.

ANDRITZ, with decades of expertise in fiber processing, uses advanced techniques to enable customers to create products, not only sustainable, but also high-performing and visually appearing, whether it comes to trays, containers, coffee lids, cutlery or packaging - ANDRITZ Dry Molded Fiber technology is a viable alternative to plastics across industries.

❌ Made from fossil fuels

❌ High water and energy consumption

❌ Not biodegradable

❌ Often incinerated or land filled

❌ Breaks down into microplastics

❌ Harms marine life and ecosystems

❌ Under restrictions in Europe

✅ Made from renewable, plant-based fibers

✅ Less water and energy usage

✅ Fully compostable

✅ Recyclable

✅ No fossil fuels needed

✅ Easy post-industrial waste recycling

✅ Adjustable for a range of applications

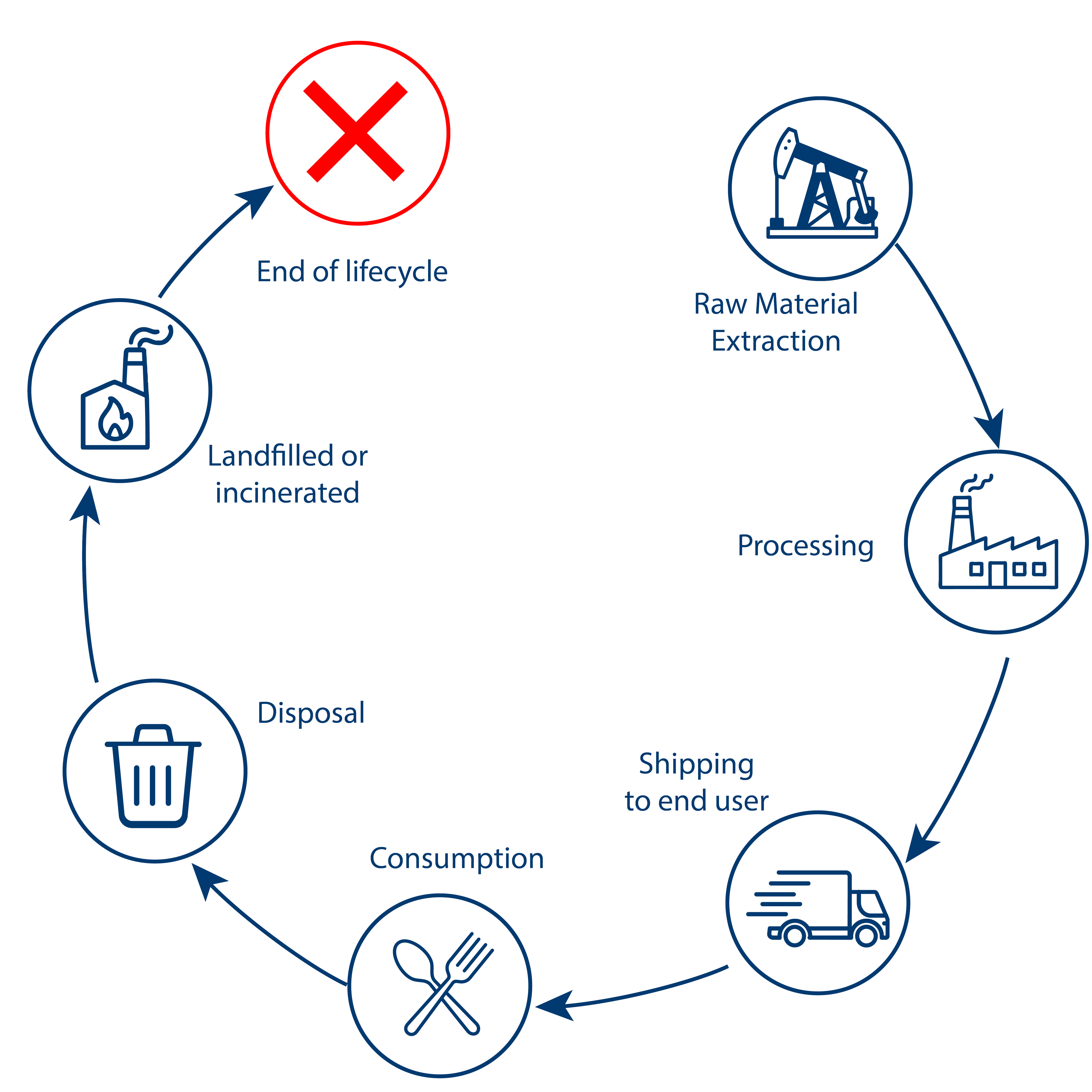

Lifecycle of single use plastic items

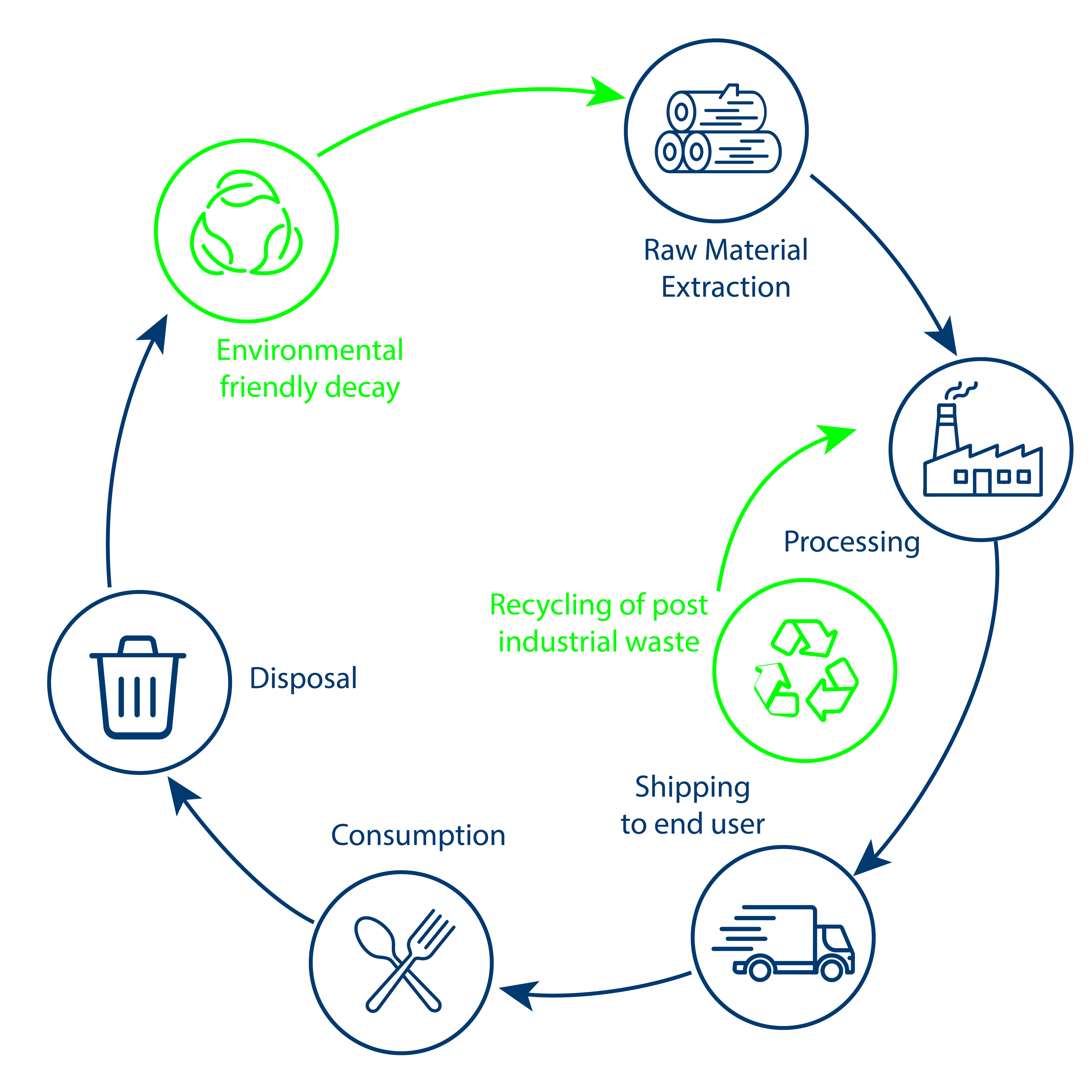

Lifecycle of single use Dry Molded Fiber items

Mat forming

Cellulose pulp is grinded and air-layed on a conveyor using airlaid or mill-to-web forming units .

Barrier applications

Barrier product is sprayed on the pulp mat to give desired properties based on end product requirements.

Compression Molding

The fiber mat is conveyed and pressed under heat and pressure in a mold, allowing bonding between the fibers and giving mechanical strength to the product.

Recycling

All the fibers not used during compression step and grinded again and sent back to the first step. Thanks to this step, up to 99% of the raw material is used to form products.

No drying ovens. No water removal. Just clean, efficient production.

ANDRITZ decided to combine its expertise with the know-how of the Dry Molded Fiber technology owner PulPac.

As a result of the collaboration, ANDRITZ is able to offer complete Dry Molded Fiber lines, further expanding its broad portfolio of sustainable solutions.

To get further information about the partnership, click the link below.

✅ Up to 95% less water than wet molding

✅ Up to 80% less lower CO₂ emissions

✅ Up to 10x faster production speed

✅ Fully recyclable and composable

✅ Extensive selection of applications to replace plastics and wet molded fiber

✅ Coffee cup lids

✅ Cold drink lids

✅ Cutlery and trays

✅ Medical packaging

✅ Consumer electronics packaging

✅ Sustainable raw material source

✅ Mechanically refined

✅ Delivered in roll form for easy integration into the DMF process