ANDRITZ supplies the complete package ranging from debarking, chipping, screening, washing and refining

Chip washing systems for panel board production

The ANDRITZ chip washing systems are designed for high efficiency at low waste water discharge.

Clean raw materials improve the quality of the final product, and prolong the life of the wear parts in downstream systems. The only way to effectively clean chips is using a wet process which removes foreign particles and impurities on the surface of the chips.

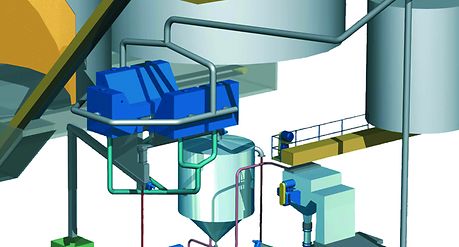

ANDRITZ chip washing system

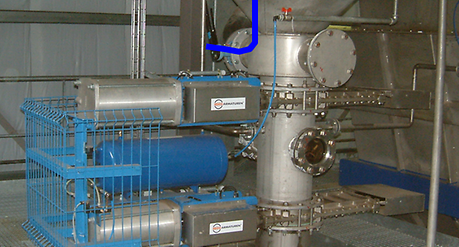

ANDRITZ chip washer

Foreign particles such as stones, nails, etc. are removed first in the ANDRITZ chip washer. Fines and particles sticking on the surface of the chips are removed by the second washing stage and discharged with the wash water at the dewatering screw. In the case of extremely dirty materials (e.g. un-debarked chips, chips from open piles, etc.), an additional washing stage might be necessary to obtain the highest chip cleanliness before the dewatering screw.

ANDRITZ chip washing systems are designed to clean the wash water, so sufficient volume of water can circulate without requiring large amounts of fresh water. Wash water cleaning is possible through gravity and mechanical process steps for high impurity removal from the system.

In order to increase thermal efficiency and reduce energy consumption, squeeze-out water from the plug screw feeder of the pressurized refining system is fed to the chip washer to heat up the wash water. This increases the wash water temperature without the need of additional external heating systems.