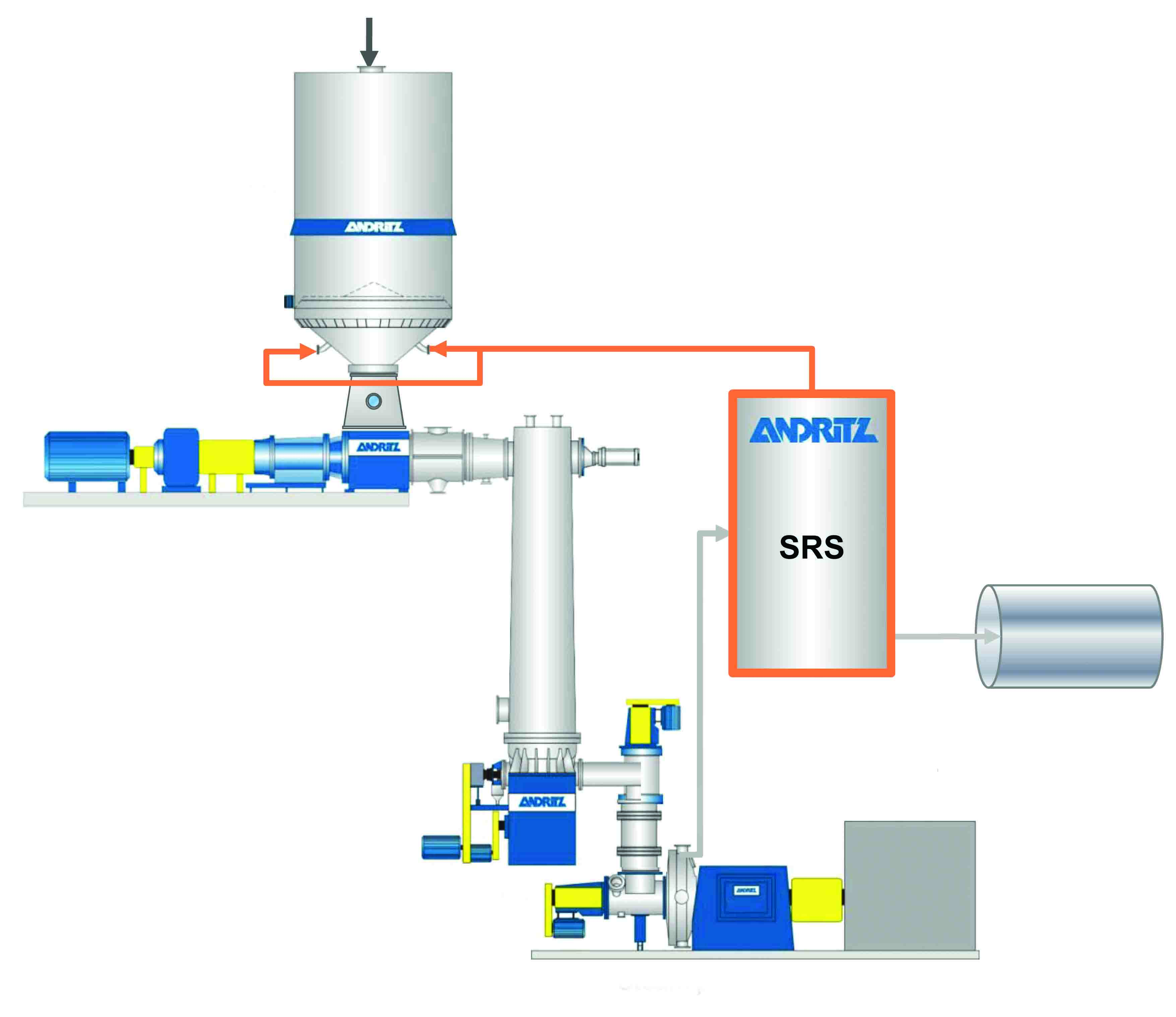

Steam Recovery System SRS

Major steam savings for greater thermal efficiency

The ANDRITZ Steam Recovery System SRS recovers surplus steam efficiently from the blow line in front of the gluing section and dryer. The recovered steam can be reused in the existing pre-steaming bin to heat up and condition the raw material in the system, which significantly reduces the amount of fresh steam required.

A smart control system ensures that the steam recovery system is operated safely and with optimized efficiency over the entire range of production capacities.