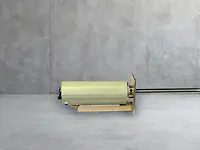

Diamond Power boiler cleaning systems are available in steam, air, high pressure water, and dual-media air heater cleaning configurations. With our deep expertise in boiler cleaning, you can depend on low maintenance, reliability, versatility and maximum cleaning performance.

Improve boiler efficiency and reliability

We specialize in keeping your boiler systems running at their best. Our advanced cleaning technologies, like high-performance sootblowers and dual-media air heater solutions, are engineered to remove ash and slag buildup, ensuring optimal heat transfer and preventing costly pluggages.

We go beyond cleaning with smart monitoring tools, including high-definition cameras, infrared sensors, and temperature measurement probes that give you real-time insights into boiler conditions. These systems empower operators to detect inefficiencies early and take proactive action.

Our intelligent control systems automate sootblowing to optimize cleaning, while our extensive inventory of replacement parts and retrofit solutions helps extend equipment life and improve reliability across a wide range of boiler models.

Whether you're in power generation, pulp and paper, biomass, or waste-to-energy, we deliver the expertise and technology to keep your operations efficient, dependable, and future-ready.

Extend boiler runtime

We help extend boiler runtime by combining intelligent Diamond Power sootblowing systems with advanced monitoring technologies that keep boilers clean, efficient, and predictable. Automated cleaning cycles target problem areas before buildup occurs, while high-definition cameras and real-time sensors give operators instant visibility into boiler conditions. This proactive approach minimizes unplanned outages, streamlines maintenance, and ensures continuous, reliable operation across diverse demanding industries. Contact us today for automated boiler cleaning!

Monitor boiler performance in real-time

We deliver powerful Diamond Power boiler monitoring solutions that give operators real-time visibility into system performance and conditions. With high-definition cameras like Wall-Eye HD and SmeltCam AT IV, teams can safely inspect boiler interiors and smelt beds with precision, even in extreme temperatures. Integrated infrared sensors and temperature measurement tools provide continuous data, while the Titanium Intelligent Sootblowing Systems (ISB) help detect inefficiencies and prevent damage before it occurs. These technologies work together to reduce downtime, improve safety, and keep boilers operating at peak efficiency.

Ensure safety and environmental compliance

We provide safeguards and alarms for potentially dangerous operating conditions. We help customers meet demanding safety and environmental standards with Diamond Power technologies designed to protect personnel, equipment, and the environment. In the utility sector, where emissions regulations are tightening, our intelligent sootblowing systems maintain clean heat surfaces to reduce particulate emissions and support compliance with EPA and local air quality mandates. Automated cleaning controls ensure consistent performance while minimizing manual intervention and supporting accurate environmental reporting.

Safety is especially critical in recovery boiler operations, where high temperatures, pressurized systems, and hazardous materials pose serious risks. The Diamond Power high-definition cameras and infrared sensors allow operators to monitor smelt beds and combustion zones remotely, reducing exposure to dangerous conditions. Our port rodders and smelt spout cleaners take safety even further by automating some of the most hazardous manual tasks. Port rodders clear air ports without requiring direct operator contact, reducing the risk of burns and exposure to toxic gases. Smelt spout cleaners handle routine cleaning and maintenance of smelt spouts, minimizing the need for personnel to work near molten material and improving consistency in cleaning cycles.

Together, these innovations help facilities operate more safely, meet environmental regulations, and maintain high performance with confidence.