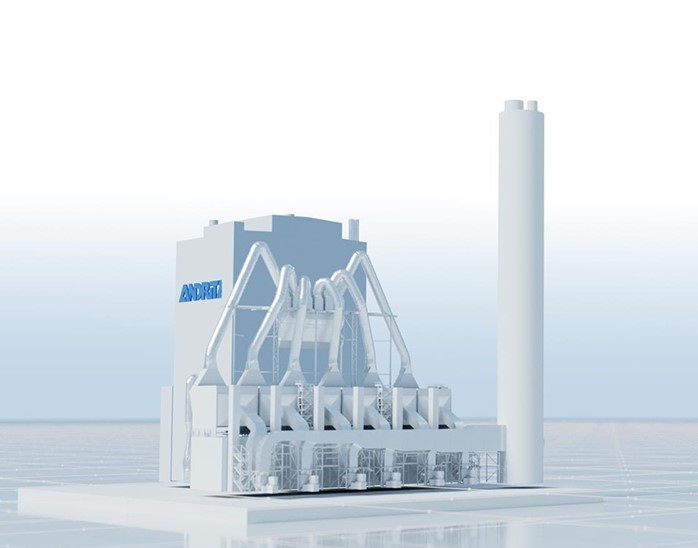

Number one in recovery boilers: Market leadership with decades of experience

A proven track record brings significant value to all recovery boiler customers. With a large installed base, ANDRITZ has supplied recovery boilers all over the globe, including those with the world’s highest capacity. Our smart solutions combine world-leading recovery boiler expertise with the latest Metris digital innovations to increase the level of recovery boiler autonomy. With our high-performance boilers, we can provide customers high lifecycle efficiency with low lifecycle costs. ANDRITZ recovery boilers have world’s highest availability, with long cleanability and durable design. Our recovery boilers are number one in efficiency: high energy, high pressure, high temperature, high recovery. We are a reliable partner and deliver as promised.

Our continuous research and development activities focus on supporting customers in achieving sustainable production with higher capacities as well as higher energy efficiency. At ANDRITZ there is also an added focus on minimizing the consumption of energy, chemicals, and water in a safe and environmentally friendly way. Occupational, environmental, and operational safety are our key priority. New recovery boiler technologies concentrate on the by-products of pulp production and on creating green energy.