Optimization, data analysis, augmented reality

Log yard cranes

Improved log yard efficiency with the ANDRITZ log handling systems

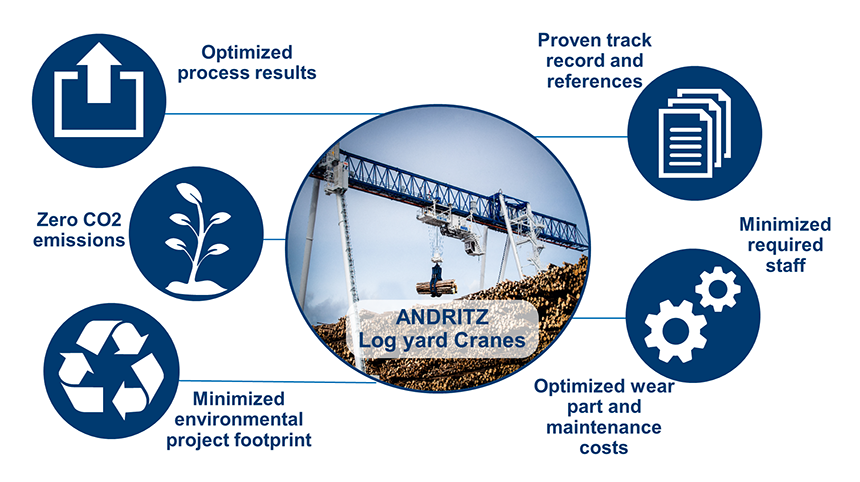

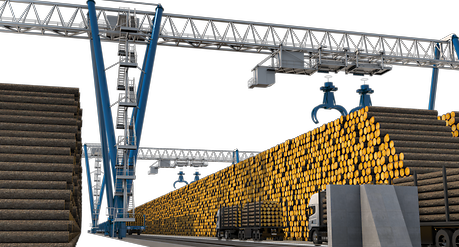

The ANDRITZ log yard crane improves woodyard efficiency and lowers overall costs.

The ANDRITZ log receiving process

Improved efficiency with ANDRITZ log yard cranes

Forest product companies face the challenges of improving the efficiency and productivity of their wood handling operations to reduce operating costs. The log yard operation is sometimes overlooked as a place where investments can produce significant returns in terms of savings in manpower, savings in wear and spare parts, and large increases in wood handling efficiencies.

The ANDRITZ log yard cranes

The ANDRITZ log yard crane is a single piece of equipment which replaces multiple loaders and requires much less maintenance and attention.

Installing the log yard crane typically reduces woodyard operating costs by a large percentage:

- It requires much less manpower to operate (compared to a loader-operated yard) when processing an identical volume of logs.

- Mills operating a log yard crane typically has less fiber loss and log breakage than with their loader operations.

- It is fully operated by electricity, eliminating the cost of diesel fuel required by loaders.

The log yard crane handles the unloading and storing of logs, and feeding to the mill, all in one unit. It can make as many as 40 picks per hour (if travel distances are kept to a minimum). This allows for a high number of trucks to be unloaded when necessary. It is equipped with storm brakes and can operate in all weather conditions, even in high-wind locations.

ANDRITZ log yard crane can replace up to four mobile loaders, and enables up to 50% savings in operation costs.

Metris ANDI – the Autonomous Crane AI

ANDRITZ has developed an artificial intelligence that constantly monitors the real world. Metris ANDI is the first crane AI worldwide, that allows fully autonomous operation with loose wood. Laser scanners, cameras, and the internal data from the crane provide sufficient information for ANDI to determine the location and dimensions of the relevant objects in the surrounding world.

ANDI works 24/7, improves safety and ensures that all operating instructions are enforced at all times. The implementation of ANDI allows a detailed tracking and classifying of the wood receiving in real-time. It helps to control the inventory transactions and optimize the debarking and chipping process. The pulp production process also benefits from the increased chip quality and reduced operating costs.