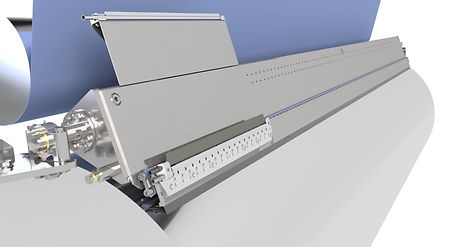

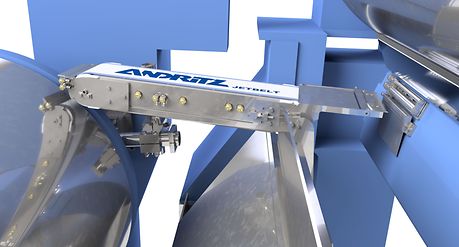

PrimeFeeder JetBelt vacuum conveyors are equipped with the latest drum motor technology and patented vacuum generation. Vacuum chambers in the unit are highly efficient and individually adjustable for proper and safe transfer of the tail. The required vacuum is generated using pressurized air by advanced injectors located inside the conveyor frame. These injectors achieve a negative pressure of more than 5000 pascal over the entire surface of the strainer.

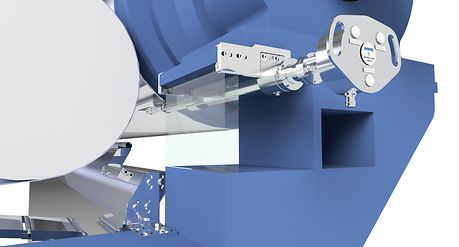

A fully integrated motor guarantees a compact design that is unique on the market, also enabling installation for demanding rebuild tasks with limited space. Despite the compact design, the engine can produce 15 kW power and does not even have to be cooled. A value unmatched in the market comparison. So your vacuum conveyor is never at a standstill.

PrimeFeeder JetBelt vacuum conveyors can be used in all sections of the paper machine, for all basis weights and all machine speeds. They are extremely robust and easy to clean.