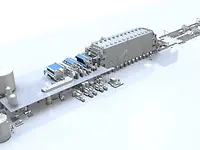

High throughput, high quality, environmentally sound fiberlines

Keeping production capacity high while keeping the mill’s environmental impact low is a major challenge for the chemical pulping industry. There are many factors critical to success – in addition to throughput and environmental excellence – which are required to maintain competitiveness.

ANDRITZ technology developing in collaboration with the world’s pulp producers

Fiberline technologies that use raw materials efficiently and that are also environmentally benign are an important step forward. Each year, ANDRITZ makes R&D investments to maintain its lead as a provider of environmentally friendly, energy-efficient, and cost-effective technologies. Every ANDRITZ fiberline process and machine is developed to have a positive impact on pulp production: high quality, high availability, high throughput, and excellent energy conservation. Investing in ANDRITZ fiberline technologies provides a technical and economic advantage – now and in the future.