Custom-tailored pump solutions for various industries.

From South to North

ANDRITZ delivers engineered pumps for water supply for subsurface station.

China is facing the difficult situation of having to provide for 20% of the world’s population with only just over 7% of the global water resources. This situation is aggravated by the fact that 80% of its water sources are in the southern part of the country, but 64% of the agricultural land is in the northern part, where more than 50% of the population lives.

To solve this problem, China started a huge water supply project in 2002. The South-North Water Transfer Project, based on three main routes – eastern, central, and western – it will transport 44.8 billion m3 of water from the wet south to the dry north of the country every year as from 2050.

The Yellow River derives its name from the yellow mud and sediments that it picks up in the Shaanxi Loess plateau.

In addition to the Yangtze, the Yellow River plays a significant role in feeding these canals. Its name derives from the yellow mud and sediments that it picks up in the Shaanxi Loess plateau. It supplies water to 155 million people and irrigates 18 million ha of the agricultural land in China.

For a sub-project of the central route, the Shanxi Xiaolangdi Yellow River Diversion Project, water from the Yellow River will be transported to a subsurface pumping station through a six-kilometer-long tunnel. It is based on two reservoirs, several tunnels, subsurface channels, pumping stations, pipelines, and aqueducts and is designed to divert 247 million m3 of water annually. Irrigation will account for 116 million m3, industrial and urban water demand for another 116 million m3, and 15 million m3 will be used for ecological purposes. The pumping station is equipped with four hydraulic machines that pump the water over a distance of 60 km to an artificial lake in the Shanxi Province.

The infrastructure expert

As the best candidate in the call-for-tenders assessment process concerning project requirements and detailed proof thereof, ANDRITZ was awarded the order to deliver the pumps for the subsurface station. ANDRITZ already assisted in other sub-projects of the South-North Water Transfer Project in the past. At the Hui Nan Zhuang station, for example, eight ANDRITZ horizontal, double-suction split-case pumps supply drinking water to the Chinese capital of Beijing, 60 kilometers away.

At the Hui Nan Zhuang station, eight ANDRITZ horizontal, double-suction split-case pumps supply drinking water to the Chinese capital of Beijing, 60 kilometers away.

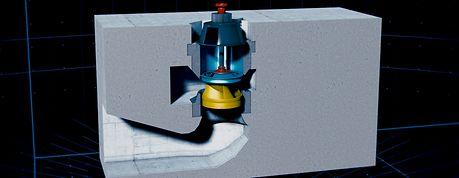

The 4 two-stage vertical volute pumps for the Shanxi Xiaolangdi Yellow River Diversion Project will be customized to meet the project requirements. Each of them achieves a flow rate of 5 m3/s over a head of 236 meters at an output of 13 MW. Their appeal lies in the efficiency of more than 91%. As the Yellow River conveys large quantities of sand, the pumps will be provided with a special abrasion-resistant coating.

The hydraulic dimensioning and design of the volute casing depends on the specific output characteristics. Optimum flow in the volute is achieved due to its individual shaping, which also guarantees a high level of efficiency. By varying the trailing edge, high-precision adjustments can be made to the desired duty points. The volute casing is designed as a metal volute. This is a welded structure consisting of several segments, which optionally can be embedded in concrete. A solution without concrete lends itself to the Shanxi Xiaolangdi Yellow River Diversion Project because higher delivery heads are necessary, which, due to the strength requirements, cannot be handled with a concrete volute.

ANDRITZ two-stage vertical volute pump for the Shanxi Xiaolangdi Yellow River Diversion Project

The guide vane mechanism is opened and closed in a continuous process. The guide vanes are individually connected to the operating ring by means of articulated levers. This ring is actuated via hydraulic cylinders and rotates the guide vanes into the desired position. A guide vane mechanism is an emergency closing element in case of difficulties with the electric power supply, but it can also be closed to keep the power input to a minimum if synchronous motors are used during start-up. By closing the guide vane mechanism it is as well possible to start up the pump when the pressure pipe is full. This guarantees a short start-up time with minimum power input.

Delivery, installation, and start-up of the ANDRITZ pumps are scheduled to take place in about two years. This will be another successful step for China towards obtaining a sustainable water supply in the north of the country.