Agrochemical & fertilizer solutions with a heart for nature

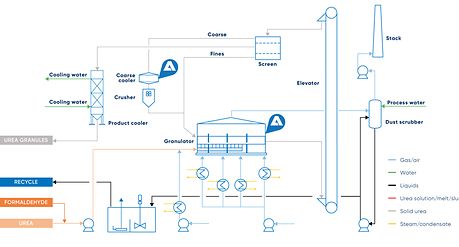

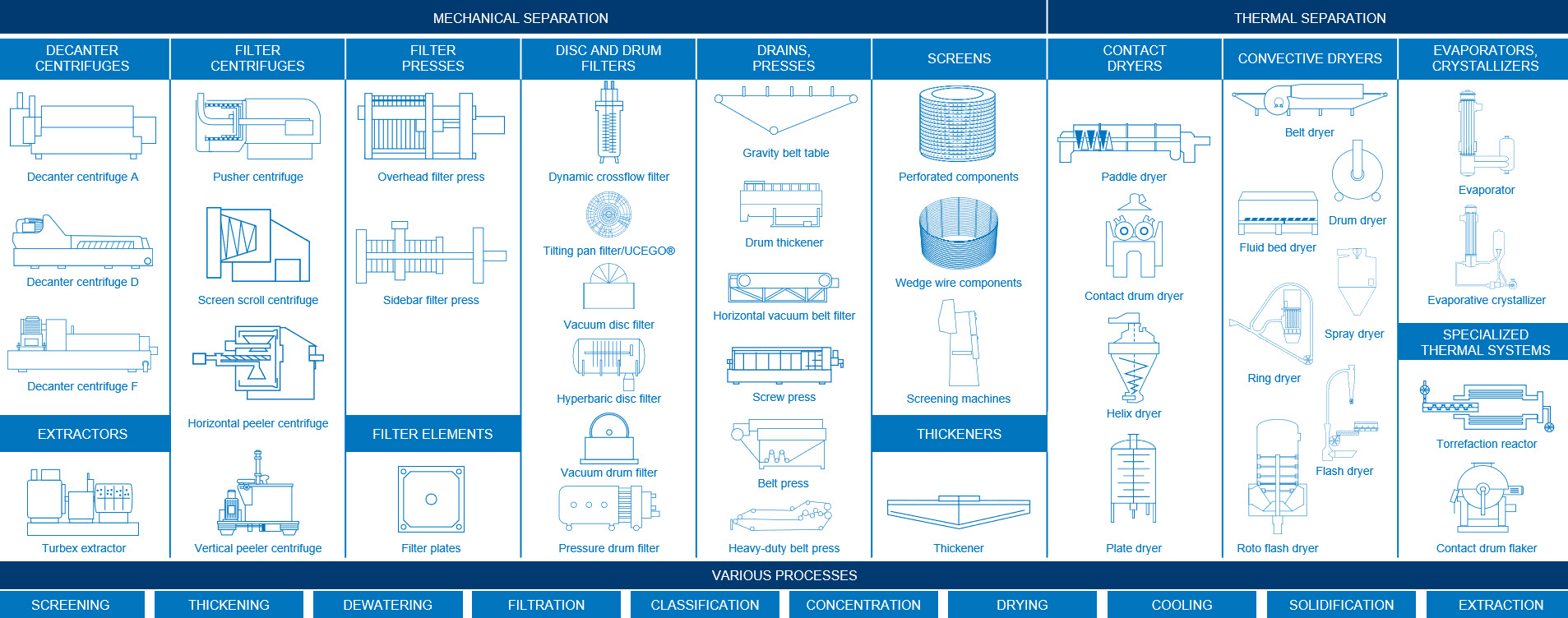

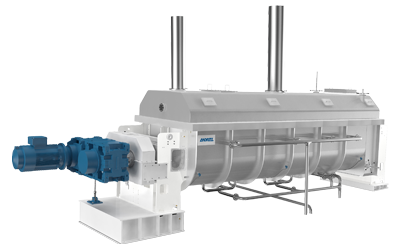

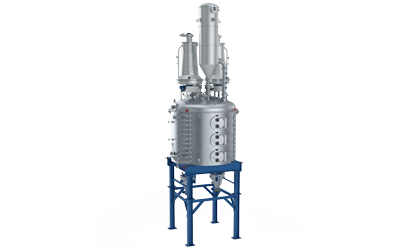

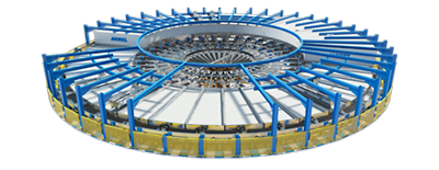

With our extensive portfolio of solid/liquid separation technologies and team of separation specialists, ANDRITZ has both the capability and deep desire to create an environment where nature and humans can flourish and thrive. Centrifugation, drying, separation or filtration, however your product is created, we most likely have everything to produce it: the technology, the process knowledge, and also the service and automation solutions.

In our pilot plants around the world, next-gen dewatering, filtration and drying solutions are developed and tested. Whether you are a start-up with an innovative idea for creating a new biofertilizer or reducing CO2, or a partner with the need to improve efficiency in an existing process, our team is ready to support – all backed by proven service and innovative automation solutions.