Put our 150 years of OEM experience to work!

Dairy

A broader approach to tackling tomorrow’s dairy challenges

What’s the next big opportunity for your business? Despite having worked with thousands of dairy customers over the years, the answer to this question is never quite the same. Whether it’s boosting your margin on white-label products or ensuring the superior quality of a branded product, it all comes down to your ability to choose from one of the industry’s broadest ranges of separation solutions. Solutions that meet the fast-changing needs of today, and for years to come.

ANDRITZ Gouda drum dryer

Drum dried milk powder - More chocolate, lower cost

Ever since developing the world’s first drum dryer in 1916 and our first mill sifter a year later, we’ve built a global reputation in the food industry for providing robust, high-quality drum drying processing lines. With more than 500 dryers installed for milk drying alone, we’ve proven ourselves to be a capable partner for handling everything from the engineering and design to installation and start-up.

We can test your materials in our pilot plants to help achieve your goals in terms of taste, purity, and product characteristics. In addition to its high concentrations of free fat, which enables you to reduce the amount of cacao butter, drum dried milk powder also maintains excellent fluidity in the chocolate mass while giving the milk powder a distinctive caramel taste.

ANDRITZ SEPARATION equipment for drum dried milk powder:

- ANDRITZ Gouda drum dryers

- ANDRITZ Fluid bed coolers

- ANDRITZ Gouda Mill sifters

Dynamic crossflow filter DCF designed for food applications

Fluid bed dryer and cooler for milk powder production

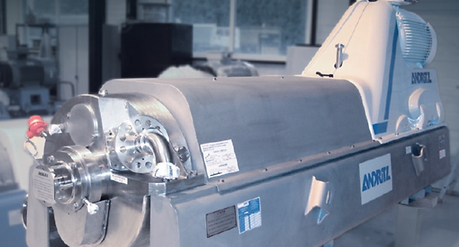

F-Decanter for casein production

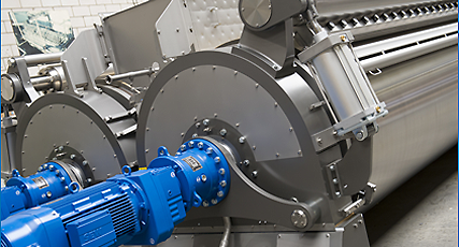

ANDRITZ decanter centrifuge D for efficient sludge thickening and dewatering

Casein production - The smarter way to a better product

Decanter centrifuges have been used in the dairy industry for over 100 years, and the development continues. Since our first casein installation in 1970, we have continued to refine our solutions, developing low-foam features that reduce the need for chemical defoaming agents. With this innovative approach to casein decanting, the end product is not only free of chemicals – a key potential allergen – but is also less costly to produce, with some customers saving up to 25,000 euros a year in defoaming agents alone.

This work has led to a generation of decanters for the production of casein that performs continuously, is easy to maintain and clean, and produce a dry cake that preserves the valuable casein product. Our decanter’s performance is measured not just by its separation capabilities, but also by its “simply clever” design – delivering high availability and efficient cleaning-in-place (CIP). It’s all part of our ongoing effort to develop smarter, more efficient solutions for casein producers everywhere.

ANDRITZ SEPARATION equipment for casein production:

- ANDRITZ Decanter for de-wheying and de-watering

- ANDRITZ Fluid bed dryers and coolers

Whey treatment - Redefining operational efficiency

Few global suppliers can match the range of expertise and innovation we bring to customers in whey treatment. For decades, we’ve developed not only high-yield lactose decanters but continuously develop new technologies like the DCF.

ANDRITZ SEPARATION equipment for whey treatment:

- Krauss-Maffei DCF Dynamic crossflow filter for high concentration of whey products

- ANDRITZ Decanter for calcium concentration and lactose separation

- ANDRITZ Gouda drum dryers for drying step

- ANDRITZ Fluid bed dryers and coolers

- ANDRITZ Fluid bed spray granulator for granulation of whey

Wastewater treatment - all from a single source!

Beyond the solutions of separation throughout the process of production, ANDRITZ SEPARTION also proposes a wide portfolio of separation technologies for the waste treatment of dairy.

ANDRITZ SEPARATION equipment for wastewater treatment:

- Screens

- Decanter centrifuges for dewatering of dairy sludge

- PowerDrum drum thickeners and PowerDrain gravity belt thickeners for efficient sludge thickening