Put our 150 years of OEM experience to work!

Finest coal washing and tailings treatment

Need to increase washing efficiency? Enhance throughput? Reduce water consumption while meeting standards for environmental impact and safety?

Our separation specialists tackle these challenges based on decades of experience recommending, configuring, and commissioning a wide range of solutions for all types of coal applications. Whatever your specific need in coarse dewatering, fine dewatering or coal tailings treatment process, we have the right solution ready for you.

ANDRITZ technologies are focused on handling finer particle sizes, meet high product dryness requirements, achieve high recycling rates for process water, and maximize efficiency in the dewatering of coal tailings. We offer a wide selection of flocculation, thickening and mechanical dewatering solutions for coal producing companies of all sizes. Combined with process simulation technology, machine and process control and proven local service, we are proud to be able to offer the full package from from simulation to installation and process optimization.

Do you have questions? Get in contact with us!

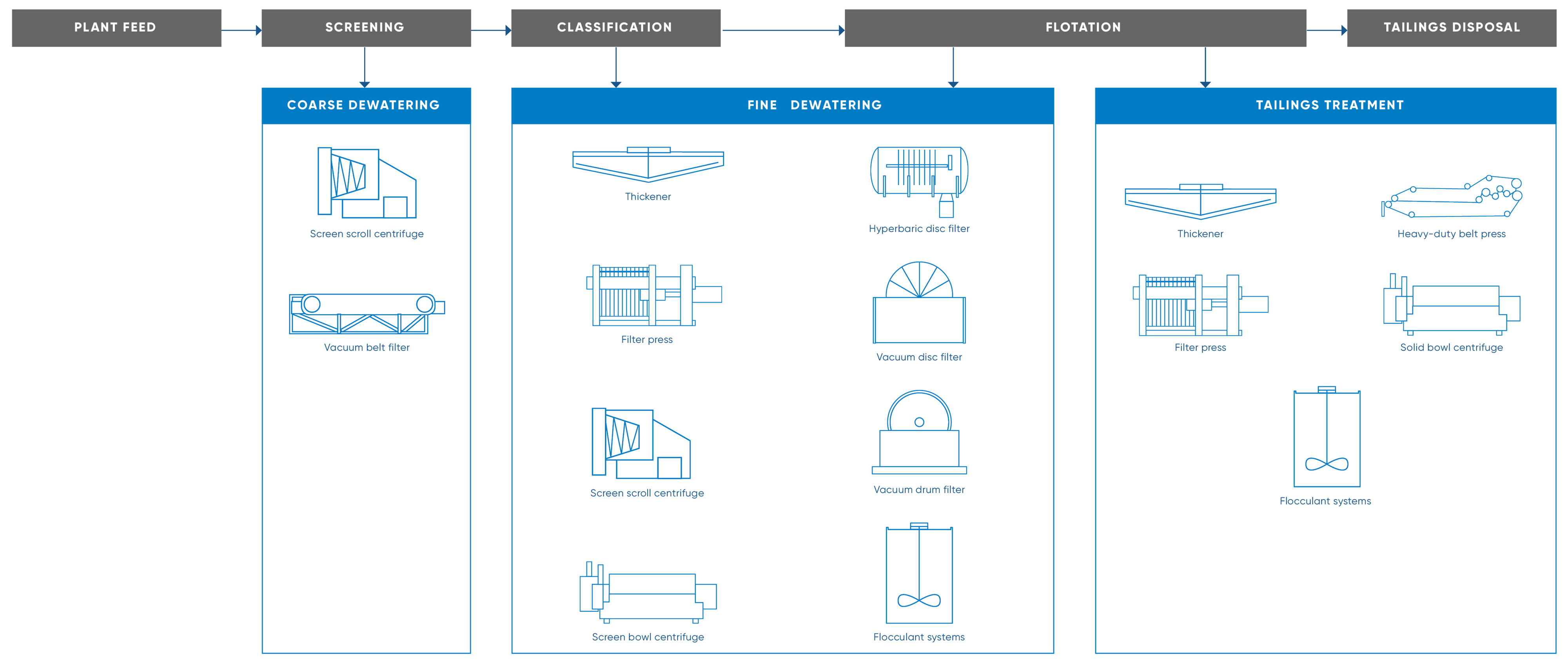

Where we fit into your process

One main advantage of working with ANDRITZ is that it offers a range of technologies to ensure that there is a best solution available to achieve the targets for any coal application. Filter presses, various types of pressure and vacuum filters, and different types of centrifuges – each is configurable to meet specific requirements. ANDRITZ specialists have the experience and skill to recommend the right solution and configure it to achieve precise performance.

ANDRITZ has invested considerably in expanding its competence in solid/ liquid separation with the acquisition and integration of such well-known names as Bird, KHD Humboldt Wedag, Rittershaus & Blecher, Netzsch Filtration, Escher Wyss dryers, Krauss-Maffei centrifuges, dryers, and filters, and Delkor Capital Equipment (Pty) Ltd.. The result is a comprehensive product offering for each dewatering step in the coal preparation process.

Browse solutions for: