Discover the ART of Recycling in our new pilot plant

Circular economy for forming fabrics started

Reutlingen, Germany, September 2022. Conservation of resources, reduction of energy consumption, CO₂ reduction, closed-loop circular economy - these are all firmly established cornerstones of ANDRITZ's sustainability strategy.

Bringing its economic, environmental, and social objectives in line with the major challenges of a raw material and energy environment going through radical changes globally is an urgent task faced by the company. ANDRITZ's R&D specialists explore and develop new technologies to make the valuable resources used in paper production sustainable during unprecedented climate change.

The R&D project "Tex2Mat" for the recycling of waste materials in the production of press felts at the main site in Gloggnitz, which has received funding and been awarded a national prize for environmental technology in recent years, shows how seriously the company takes its responsibility to ensure a futureproof, sustainable transformation. This results in the production of paper machine clothing that mitigates climate change. As a result of the consistently positive feedback from customers who have used felts made from a mixture of new and recycled material for the first time, the proportion of recycled material in press felt production is continuously being increased - thus promoting a circular economy that is sustainable in the long term.

Home base for R&D inventors: the new ANDRITZ Recycling Technology Center – for short ART – in St. Michael

AIMING TO ACHIEVE A CLOSED-LOOP MATERIAL CYCLE WITH FORMING FABRIC RECYCLING

Based on this success, ANDRITZ is now pursuing its next recycling research project about Paper Machine Clothing (PMC) for forming fabrics that are made from polyamide (PA) and polyethylene terephthalate (PET). The main aim of the new research project named "ReFibreValue", which is funded by the FFG (Bridge2 funding programme No. 895423) following the EU Green Deal Waste Framework Directive 2008/98 and the EU Circular Economy Framework.

Directive 2018/851 is the research and development of a completely carbon-neutral material cycle. From the transport of the used forming fabrics from paper production sites and the following recycling processes, including cleaning and separation of the PA and PET, to the subsequent return of the recycled material to the production of new monofilaments and production of new forming fabrics, there should ultimately be a continuous, closed-loop, resource-saving and energy-saving cycle, with the up to now usual thermal disposal of material waste associated with high CO₂ emissions being reduced to zero in the long term.

Together with partners from the paper industry and Montanuniversität Leoben (MUL – Montanuniversität Leoben), including its departments for Polymer Processing, Materials Science and Testing of Polymers, Resources Innovation Center, Waste Processing Technology and Waste Management, as well as Mineral Processing, the R&D team at the Reutlingen production site is now starting the research project and in order to achieve a positive result similar to the outcome achieved by their colleagues in press felt production at Gloggnitz.

Step 1: Used ANDRITZ forming fabrics return

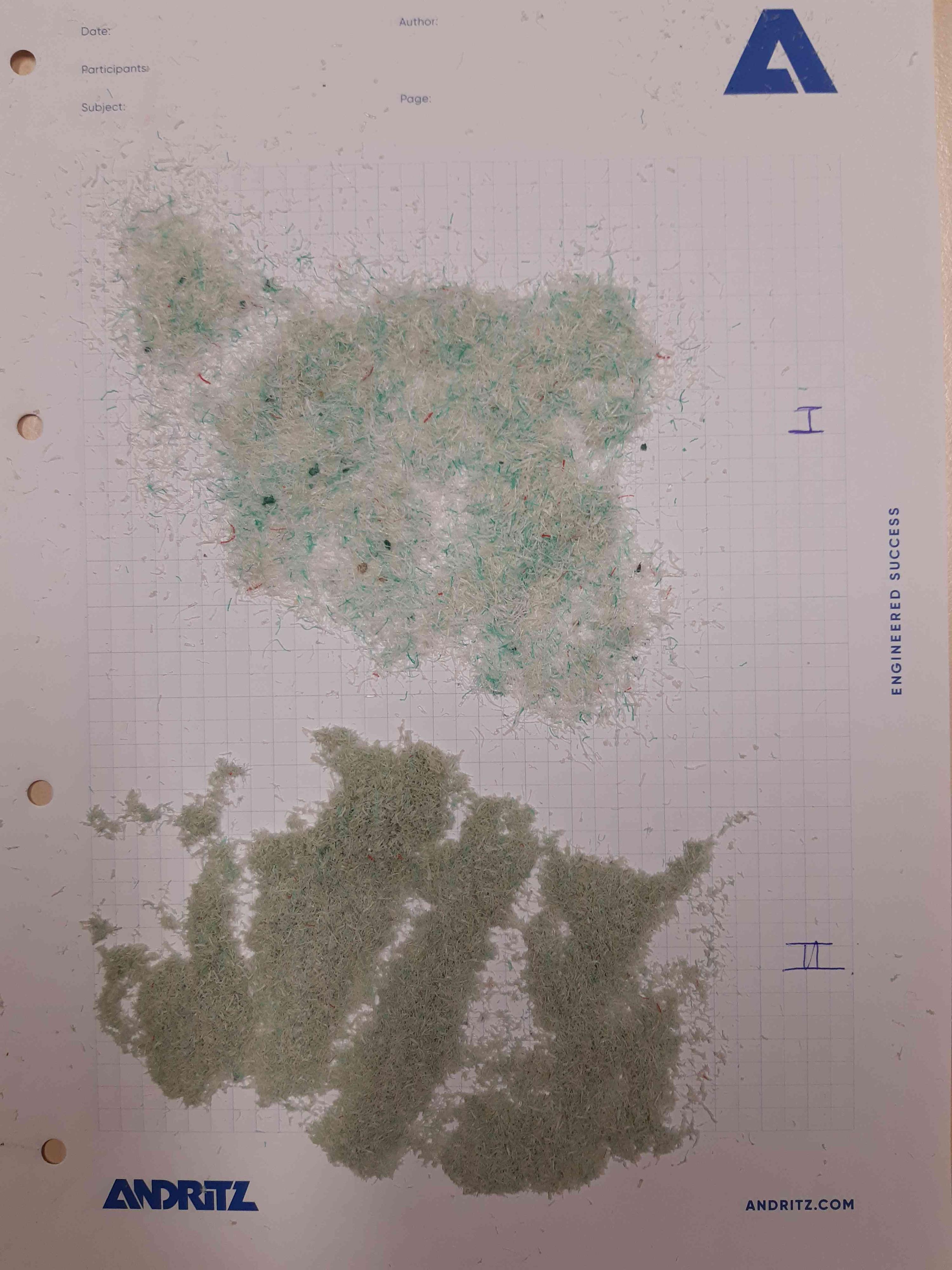

Step 2: Reduced to coarse shredded pieces

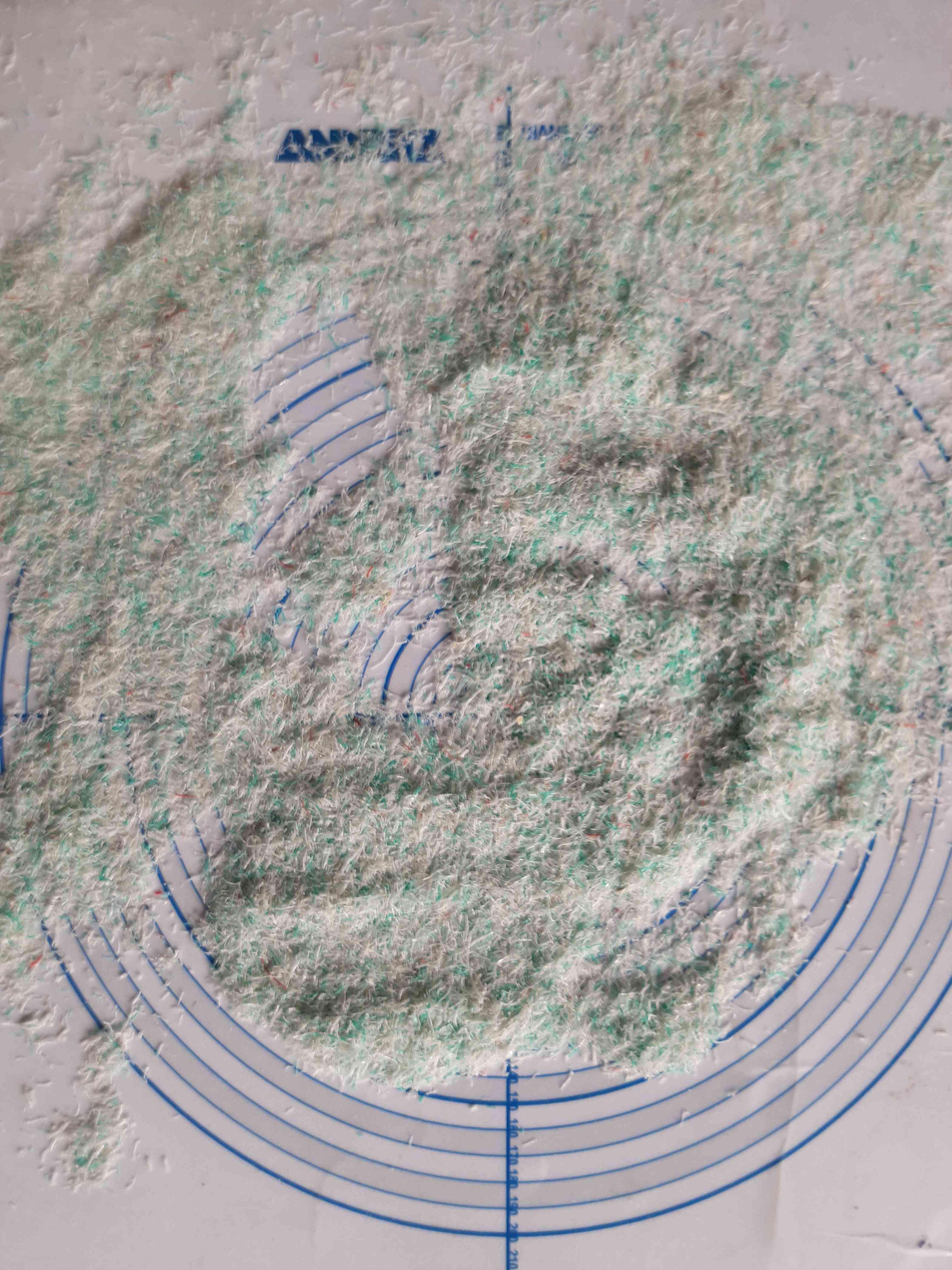

Step 3: Cutting unit in the ART Center and fine shredding

FUNDAMENTAL RESEARCH AS THE BASIS FOR NEW TECHNOLOGIES IN SYNTHETICS RECYCLING

The new ANDRITZ Recycling Technology Center – known as the ART Center – enables recycling trials to be conducted under real production conditions with industrial-sized equipment. The units can be used for primary and secondary shredding as well as for fine granulation of composite materials. ANDRITZ also has a polymer sorting process at its disposal that is characterized by high separation performance, especially when high-purity products are required and when polymer mixtures with a wide range of different particle sizes and shapes are also present. The core unit of this process is the CENSOR ACZ, a sorting centrifuge that separates, washes, and dewaters the raw material simultaneously. As a result, tests are possible with very different waste streams and complete recycling processes can be replicated.

The same site also accommodates the newly opened Digital Waste Research Lab of the University of Leoben – a research center for waste processing and waste management. The cooperation between ANDRITZ and the Montanuniversität Leoben creates synergies between research and business leading to the development of technologies and products needed to meet the future requirements of the recycling industry.

Circulyzer GmbH – a start-up and spin-off of Montanuniversität Leoben is also a vital part of the research project and supports the project with its separation technology. As the separation of the two main components of the forming fabric, (PA) and (PET) mixtures, is much more difficult than with PA synthetics exclusively used for press felts, special attention is given to this process.

So far, there have been no processes for this that make separation worthwhile in terms of economics and the environment. This shows that well-founded basic research is necessary as a starting point for the entire recycling process, so that real future-oriented technologies can be developed rather than just striving to achieve quick, superficial results that then fail to achieve a closed-loop recycling economy when implemented.

This joint research initiative combining science and industry is all the more valuable when the aim is to meet the long-term requirements in polymer recycling. This may become even more important, given the sharp rise in energy prices and availability of raw materials and the need for sustainable CO₂ reduction in the future based on legal requirements, e.g., through the introduction of mandatory recycling quotas for industrial waste. Jan Freudenberg, Director R&D Forming Fabrics Global, who is in charge of the research cooperation at ANDRITZ, and his team are convinced that at the end of the research and development phase, involving intensive analysis work and extensive tests, a recycling technology will have been created that is both economically and environmentally sustainable.

Step 4: Finely shredded screening fraction and separated screening fraction