Can you tell us about the market for e-fuels and advanced biofuels and what are the driving forces that are creating the demand?

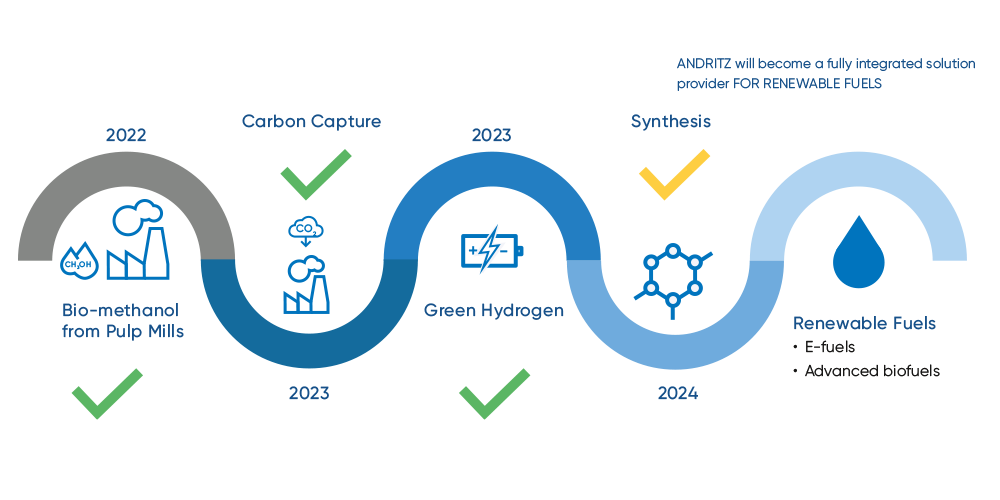

GRÖNQVIST: E-fuels (efuels or electrofuels) and advanced biofuels are gaining increasing attention as alternatives to traditional fossil fuels due to their potential to reduce greenhouse gas emissions and dependence on traditional fossil fuel resources.

The biggest driver for this change is our environmental concerns. We need to do something to alleviate climate change and it is clear we all need to reduce our greenhouse gas emissions. Other drivers are the policy support in various countries and the new directives by the European Council, RED III, which sets the bar for the need of these fuels by 2030. Also, technological innovations and advancements have made the production of different renewable fuels more viable and cost-effective.