News

ATMP process description

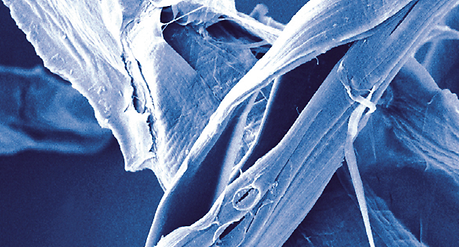

In the ATMP process, the first stage (RTFibration) is performed in a pressurized Impressafiner and a fiberizer (low specific energy refiner) to delaminate the wood chips into loose structures of fibers. With a large surface area, these bundles are perfect for targeted chemical treatment to attack the secondary fiber walls and improve the bonding characteristics in the next stage (high-intensity RTS refining).

Enhance fiber development – Reduce energy consumption

A 300-800 kWh/t energy saving for a given pulp tensile strength has been confirmed at mills running the combination of chemicals and mechanical treatment alone. The high energy efficiency and pulp quality at lower freeness in the primary stage requires less refining energy in the secondary and/or reject refining stages. Modern mills are using energy-efficient LC refiners which further reduce the specific energy consumption of the entire production line.

Benefits

- Energy savings from 300–800 kWh/t

- Higher bonding strength

- Higher brightness of unbleached and bleached pulps

- Lowest shive content

- Reduced extractives content

- Applicable for a large variety of softwood species, including spruce and pine

- Significant improvements in pine pulp properties

- Modular system – easy to retrofit

- Excellent economic payback