ANDRITZ integrates several innovative technologies to increase chipper throughput and wood chip quality.

TechNews: The next generation in screening and fractionation

Well-known with over 5,400 pressure screens installed in numerous stock preparation lines worldwide, ANDRITZ presents the latest evolution in screening – the PrimeScreen X. The innovative design of the new screen builds on the successes of the widely valued ModuScreen family, but offers innovative key benefits. The improvements in energy efficiency, screening performance, and maintainability are significant.

According to Sampo Köylijärvi, Global Product Manager for RCF screening and flotation systems at ANDRITZ, “Focusing on customers’ needs and market demands whilst benefitting from our long-term know-how in screening, the PrimeScreen X passed through all stages of product development – from the initial engineering design to prototyping and two years of mill testing – in most demanding OCC applications.”

MAIN FEATURES OF THE PrimeSCREEN X

The main design improvements of the new screen include:

Top-feed stock inlet. The design uses gravity to quickly remove heavy contaminants. With this top-down design, abrasive contaminants, that cause wear to the rotor and screen basket, are not forced to flow slowly upwards through the entire screen. Top-down also improves the removal of light rejects, preventing their accumulation in the feed area and extending the life of wearing components.

PrimeRotor and foils for increased efficiency and lower power consumption. The screen can be equipped with the new PrimeRotor, which improves screening efficiency and reduces energy consumption by up to 25%. The PrimeRotor foils are interchangeable with any other ANDRITZ foils and the rotor could be installed in any screen type available on the market.

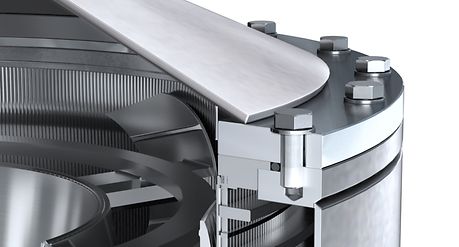

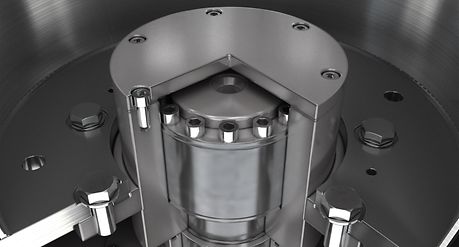

Easier maintenance. Changing baskets and rotors is time-consuming work. The PrimeScreen X uses a uniquely designed drive flange to connect the rotor to the hub, so maintenance or replacement is quick and easy. The innovative clamping system to fix the screen basket in place allows faster screen basket changes.

Optimized screen basket height-to-diameter ratios. The PrimeScreen X is designed so that the optimized screen basket height-to-diameter ratios meet the requirements of different furnishes and applications. This helps to reduce the thickening factors and leads to better control of fiber loss as well as reduced potential for plugging.

CONCLUSION

The PrimeScreen X is the natural evolution of the ModuScreen pressure screen family. The targets for this development were to improve both the energy and screening efficiency, while making the unit easier to maintain.

The PrimeScreen X is exceptional for all screening applications – brown and white grades, recycled or virgin, including coarse, fine, broke, thick stock, and fractionation duties.

The PrimeScreen X is ideal for all types of screening applications, regardless of the raw material.

Clamped screen basket design

Streamlined rotor attachment

PrimeRotor - new rotor and foil design