SEEING CHEMICAL RECOVERY IN A NEW LIGHT

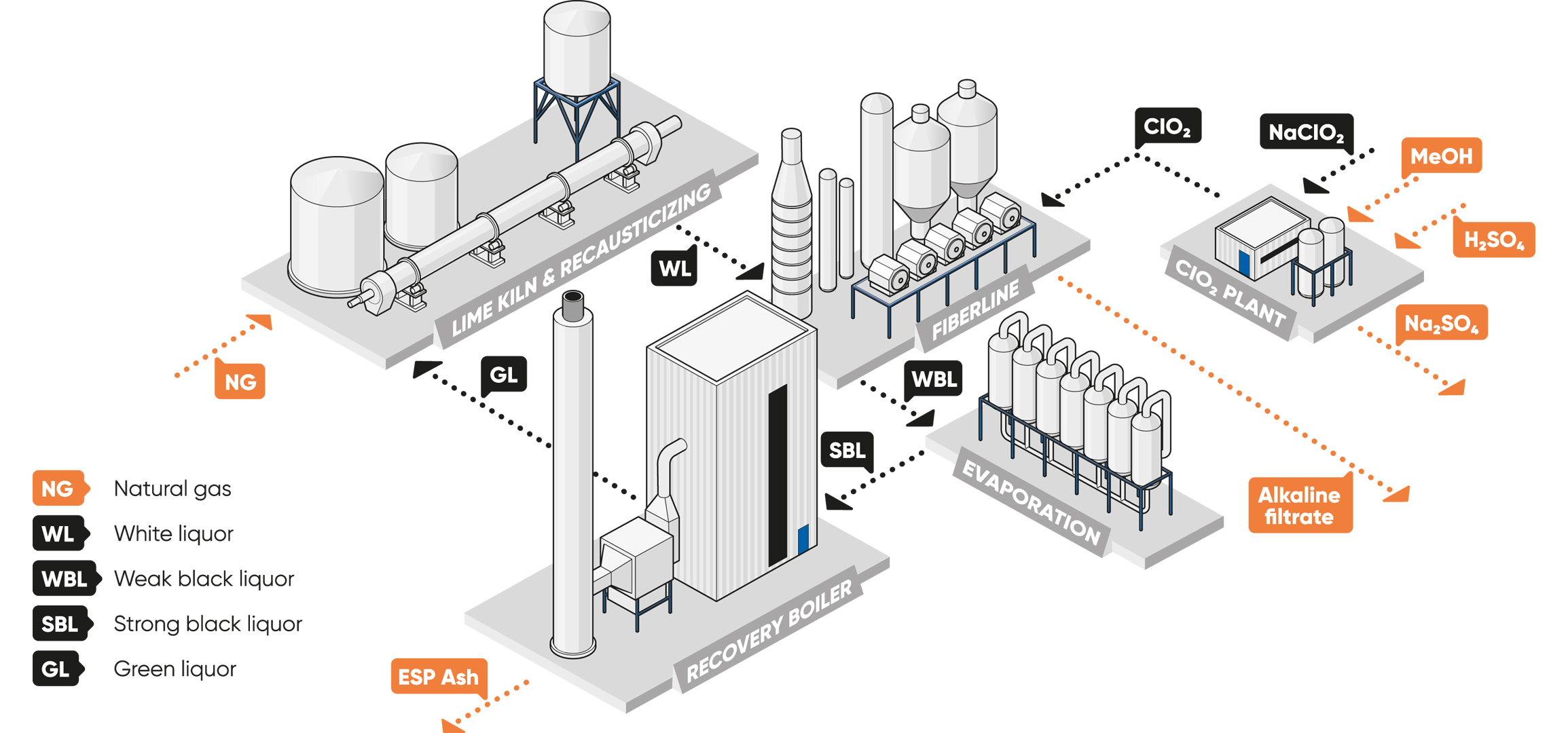

ANDRITZ was inspired to take a fresh look at achieving this by shining a new light on the chemical cycle, with two targets in mind: 1) for environmental reasons, further closing of the chemical cycle, and 2) for business reasons, converting the side streams into something of value that could be used by the mill in place of purchased chemicals and energy, or sold for additional revenue. Today, with the increased knowledge and emphasis on biorefineries and bioproducts, this potentially presents a new source of profits.

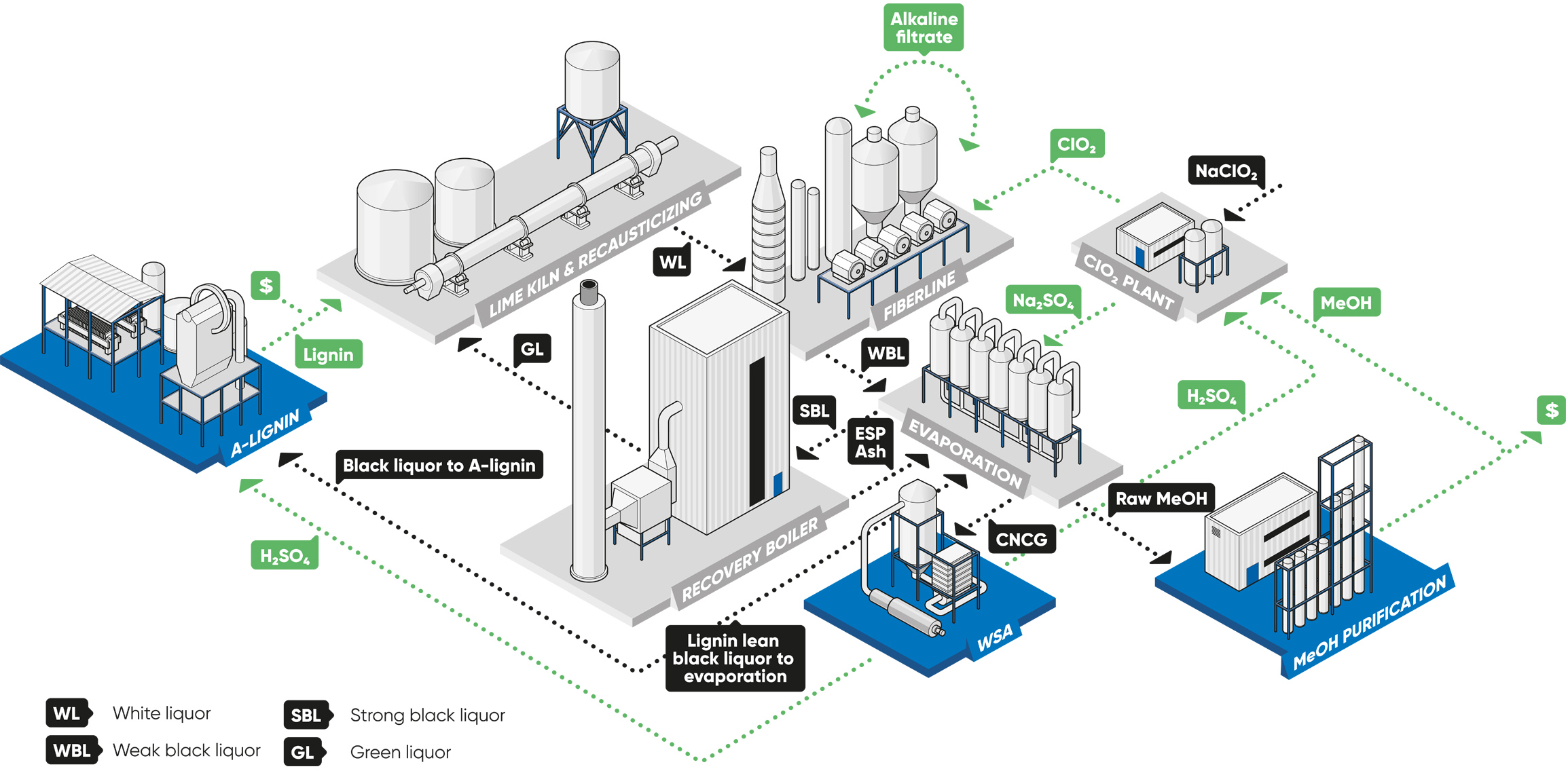

This development work resulted in a technical solution called A-Recovery+, a modular chemical recovery concept that optimizes the sodium/sulfur (Na/S) balance in a mill to increase the revenue generated and/or to reduce costs significantly. A-Recovery+ also sets the stage for pulp mills to implement a fossil-free operation.

This two-pronged approach of A-Recovery+ – environmental soundness and commercial benefit – will please mills’ process and production experts, and accountants as well. The first modules developed inside the A-Recovery+ concept generate economic value from the side streams in a traditional kraft pulp mill by adding value such as:

- Purifying raw methanol to commercial quality biomethanol

- Producing commercial quality concentrated sulfuric acid on-site

- Recovering high-quality lignin from black liquor

Development work continues to identify and unleash all the hidden potential in the side streams created during the kraft mill recovery process.

These interesting and attractive options for next-generation chemical recovery will reduce effluents and water consumption, reduce the need for make-up chemicals, and convert side streams into valuable bioproducts.