The shortest route to fiber quality. Innovative GPS navigates shortest route to fiber quality at lowest cost. Like your smartphone's GPS can guide you almost anywhere in the world, the "papermaking GPS" guides you in making the right choices about fiber mix, applied energy, and paper quality. It’s significantly reducing trial and error on your machine and saving time and money.

TechNews: IDEAS Digital Twin in Process Industries

Since the 1980s, thanks to advances in computation technologies, computer based simulation of processes using first principle models has become a well-known and widely used engineering tool for various industries. As our understanding of processes has increased, their representative models have become more realistic and sophisticated. The resulting improvement in accuracy has made simulation a fundamental predictive and diagnostic tool in process industries.

Accurate simulation can reduce engineering and construction costs, optimize process design, and improve operation performance by decreasing operation costs and increasing efficiency. In fact, simulation technology has become so advanced that it is now possible to simulate the interrelated processes of an entire pulp mill and connect these in real time to the mill’s physical operation. These sophisticated first-principles based models are referred to as “Digital Twins.”

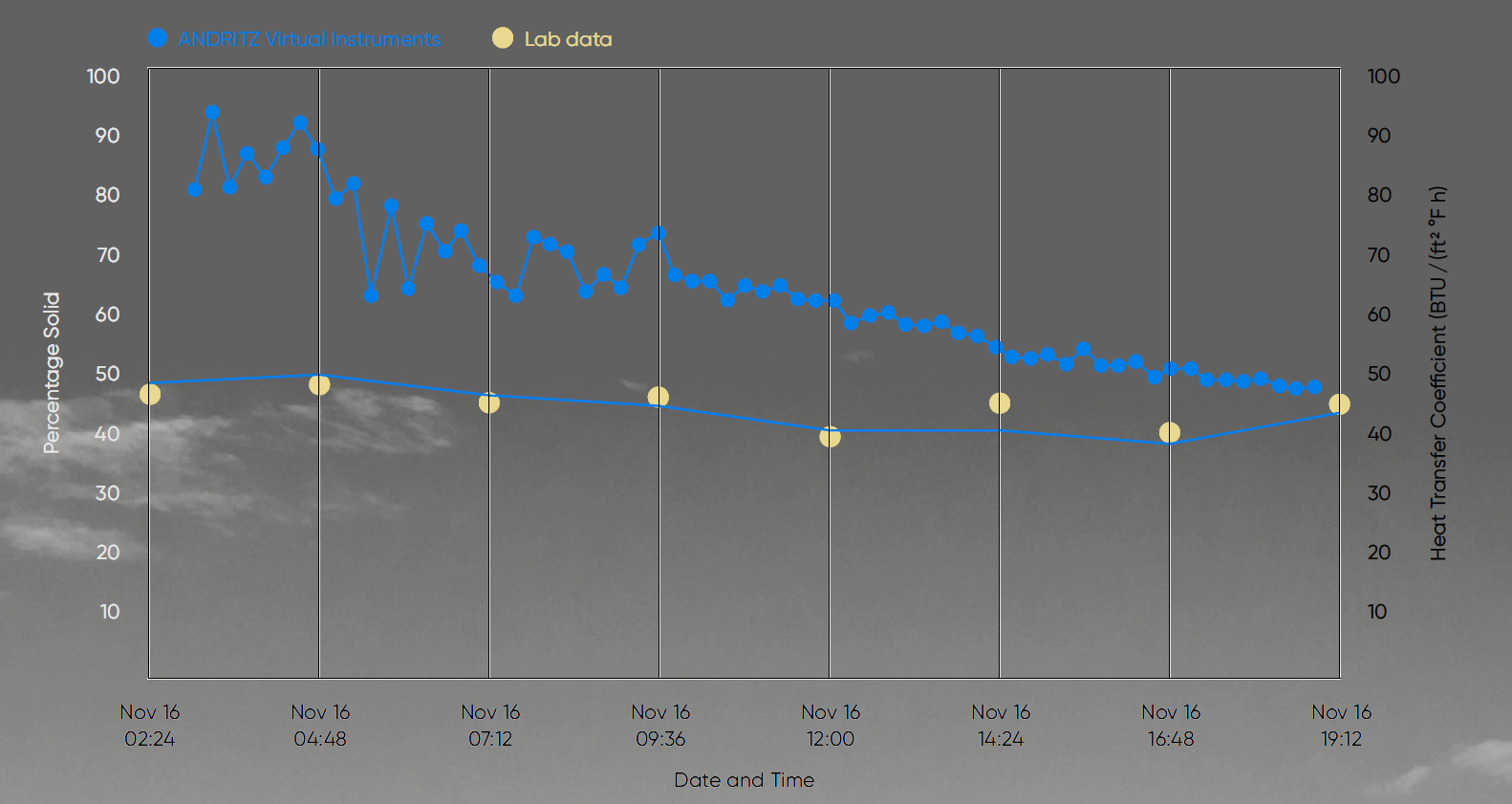

The yellow dots are the lab data points. The plot represents 82 data points at 15-minute intervals. The IDEAS Virtual Instrument predicts the percentage of solids in the evaporator (blue trace). Virtual Instrument value for heat transfer coefficient with time. The decline in value reflects fouling of the evaporator surfaces.

THE MODELS MATTER MOST

ANDRITZ provides a true Digital Twin solution for the pulp and paper industry using IDEAS simulation software and its unique execution platform. A unique feature of IDEAS is its ability to combine continuous processes with discrete events (human characteristics and interventions). This enables IDEAS to simulate pulp and paper processes spanning the entire life cycle of a mill — from feasibility studies, engineering, construction and commissioning to operation and online optimization — and then combine each individual process unit into a single, interconnected high-fidelity model.

BENEFITS OF DIGITAL TWIN TECHNOLOGY

Digital Twin applications have a wide range of uses. During the early stages of a project, Digital Twin applications can analyze the pros and cons of various design scenarios, eliminate design mistakes, identify potential bottlenecks and early engineering flaws, and inform necessary equipment specifications. Operator training simulators similar to flight simulators can be built using the digital replica of the mill. Later in the life cycle, applications can be used to measure the conditions and/or physical characteristics of a process and provide virtual measurements where real-world measurements are impossible and real-time plant wide optimization becomes possible.

The Digital Twin - IDEAS model of a pulp mill’s evaporation process.

CONCLUSION

Digital Twin technology can greatly enhance the efficiency, cost-effectiveness, productivity, and profitability of pulp mill operations, and industry-leading systems, like IDEAS, that combine high-fidelity models with real-time connectivity and an advanced operating platform, are poised to take those operations to the next level. IDEAS Digital Twin has many other applications for the engineering, commissioning, and operation.