“After testing different technologies, we have now devised proven ways to reduce NOx emissions from the recovery boiler by as much as 95%.”

Naveen Chenna

Director of Research and Innovation

ANDRITZ

The recovery boiler has come a long way since it was first invented in the early 1930s. At the time it was a revolution and is now often described as the “beating heart of a pulp mill”, as it performs its duty of recovering the inorganic chemicals, burning organic chemicals so they are not discharged from the mill as pollutants, and recovering heat in the form of steam to generate power.

Over the years, that first revolutionary recovery boiler design has developed and evolved into a showcase of sustainability for all pulp mills around the world. Hamilton Brandao, Technology Director, Recovery Boilers, ANDRITZ, says, “The recovery boiler design and function has come a very long way since its invention back in the 1930s. Safety, mechanical design, process performance, operational controls, and environmental emissions make the modern recovery boiler unrecognizable when compared to the first ones.

“Over the past two decades, in particular, recovery boiler capacity has increased steadily, while thermal performance improvement has enabled customers to not only be self-sufficient in power generation, but also create a valuable new revenue stream by selling surplus green energy to national grids.”

Naveen Chenna

Director of Research and Innovation

ANDRITZ

The modern recovery boiler may be a showcase of sustainability, but there are still some areas that need working on, in particular, NOx emissions. NOx emissions are becoming strictly monitored as they impact the environment in the long term and most countries have their own rules on allowed emissions. One example is China, which has recently seen a rapid tightening of NOx emission regulations in high density urban areas. It is expected that Europe will follow suit in regards to NOx emissions, leading to similar limits.

“In general, environmental emissions from the recovery boiler have decreased substantially over the last decades, for instance CO2, particulates and low sulfur emissions,” continues Brandao. “But this trend is not applicable to NOx, which still requires new technologies to enable a further decrease in its emissions.”

The challenge of NOx emissions from the recovery boiler is an area that ANDRITZ has been working on over the last two years and has successfully come up with a solution. Naveen Chenna, Director of Innovation and Research at ANDRITZ, says, “More than 70% of the NOx coming from a pulp mill emits from the recovery boiler. This means if a pulp mill produces 1.5 kg of NOx per tonne of pulp, about 1.2 kg is coming from the recovery boiler.

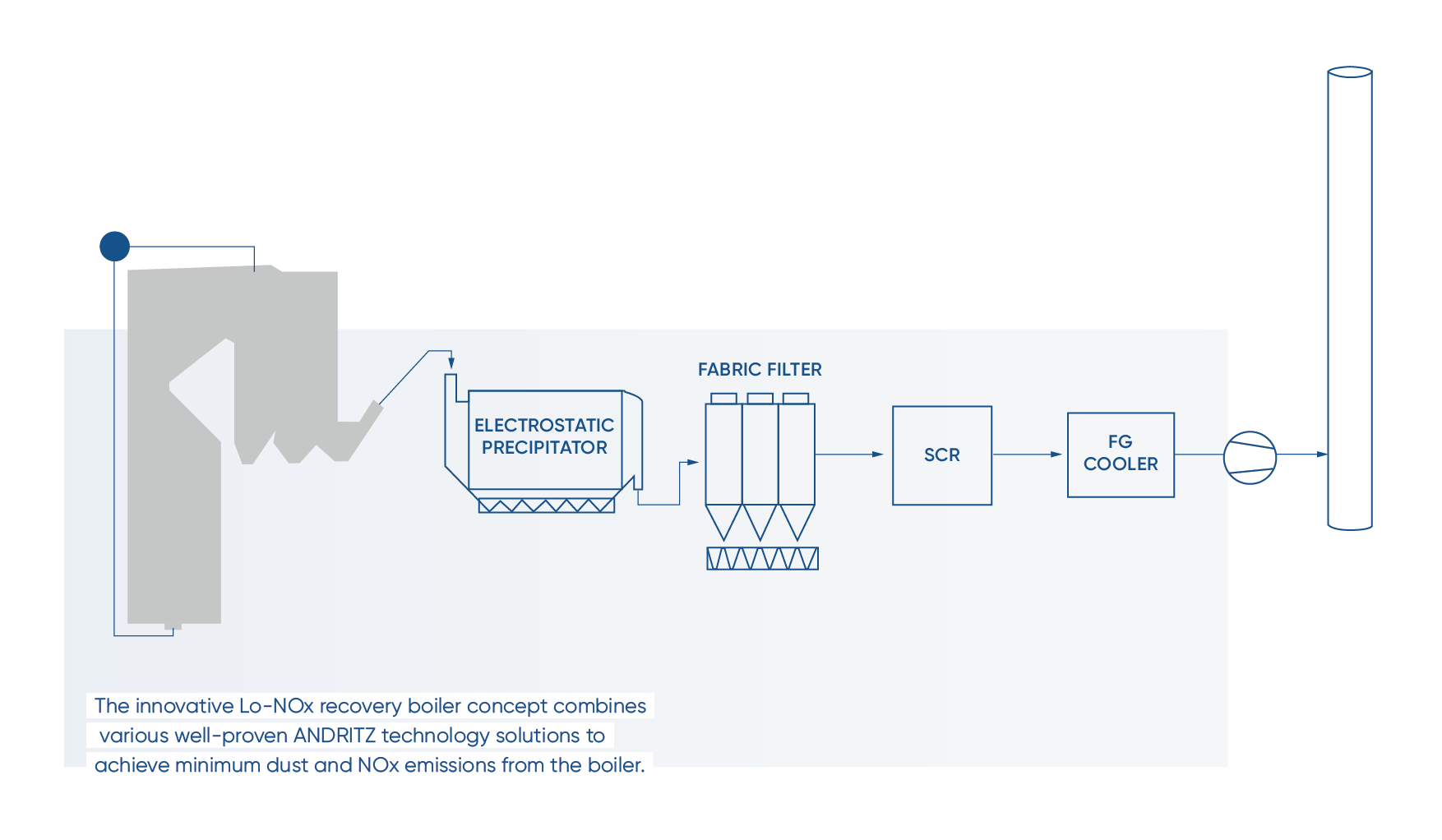

“For the last two years we have built and operated a demo plant containing various solutions at pulp mills in Finland along with earlier studies in Sweden. After testing different technologies including electrostatic precipitators (ESP), fabric filters (FF), and catalysts, we have devised proven ways to reduce NOx emissions from the recovery boiler by as much as 95%.”

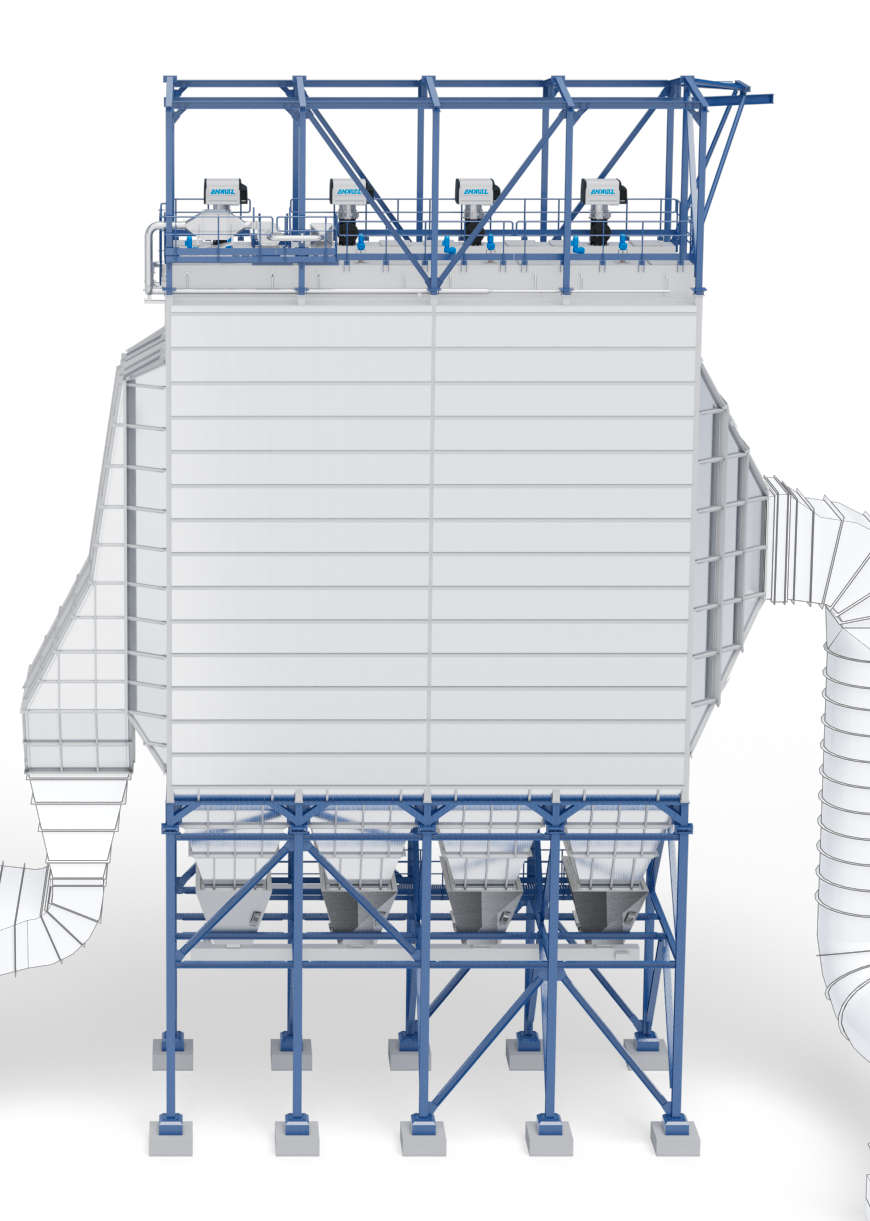

The dramatic reduction of NOx emissions is made possible by secondary methods that ANDRITZ experts have configured by using a FF for recovery boiler dust after the ESP and selective catalytic reduction (SCR). The FF ensures low dust emission and safe operation of the SCR. There are no other references of this configuration in the pulp industry worldwide, with the demo plant tests showing normal collection and release of the dust on the fabric surface.

Kasper Skriver, Global Product Manager ESP and FF, ANDRITZ, explains, “The reduction or elimination of NOx is made possible by secondary methods that can be designed to reach 95% efficiency of reduction. Particulate reduction can be achieved down to 5 to 10 mg/Nm3 with conventional ESP technology. Typical levels today range from 10 mg/Nm3 in China all the way up to 70 mg / Nm3 in Brazil.

"By applying the fabric filter technology, we will enable continuous particulate emissions less than 5 mg/Nm3, which is what we consider close to zero." The technology for NOx reduction and elimination, the Lo-NOx recovery boiler concept, is now available for ANDRITZ customers worldwide, and can be part of a greenfield mill project or retrofitted to existing mill operations.