SIGNIFICANT ORDERS FOR MONO-INCINERATION PLANTS

ANDRITZ has already received significant orders for its modular adiabatic sludge solutions, including most recently from two German companies, MVA Bielefeld-Herford GmbH, Bielefeld, and Kommunale Nährstoffrückgewinnung Niedersachsen GmbH (KNRN), Hildesheim.

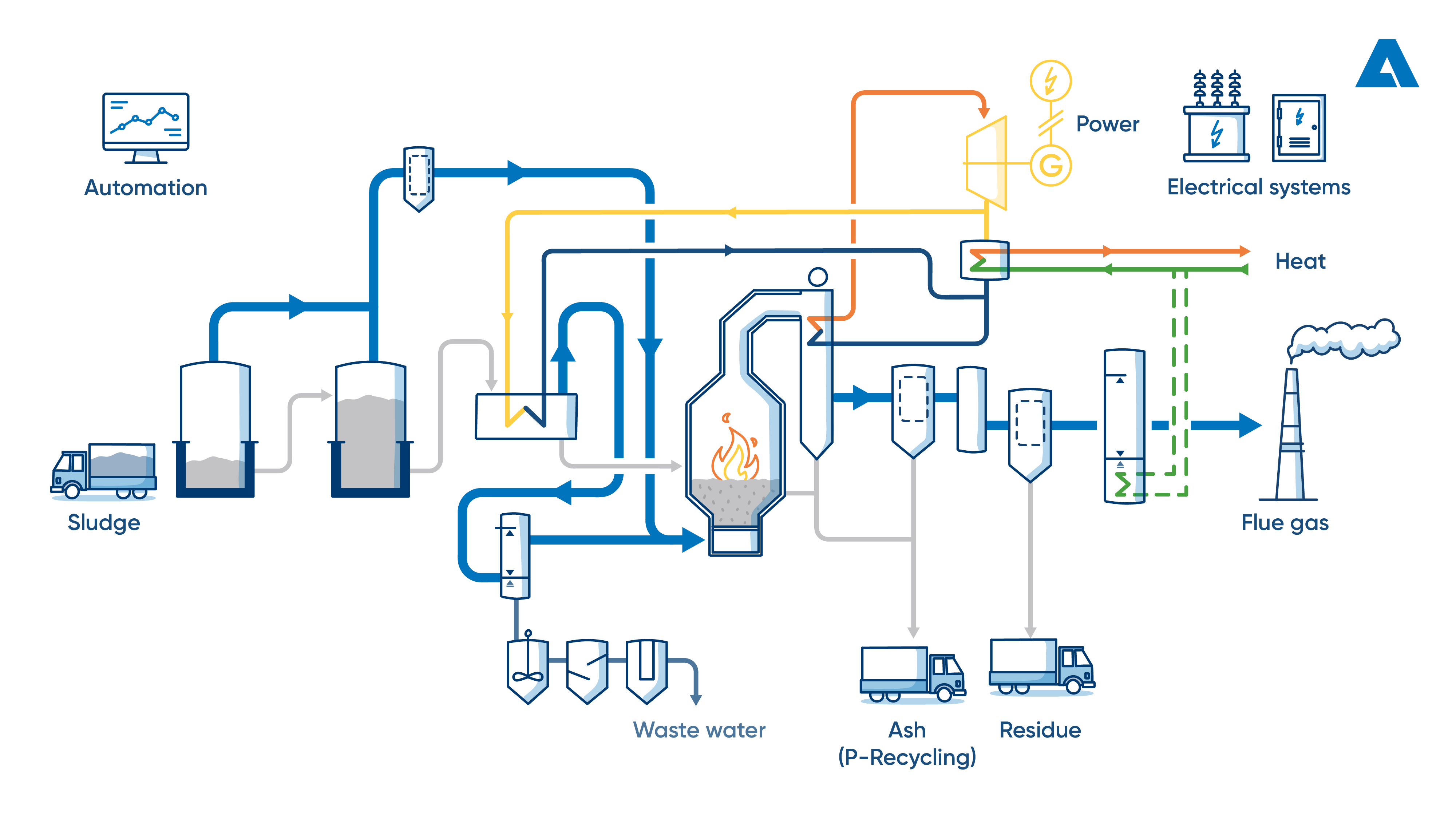

The scope of supply to MVA Bielefeld-Herford includes an ANDRITZ EcoFluid bubbling fluidized bed (BFB) boiler system for a new sewage sludge mono-incineration plant. The installation will ensure the reliable disposal of sewage sludge and enable the recovery of valuable phosphorus. Furthermore, the steam generated by incineration will be supplied to the existing waste incineration plant that produces energy for the national grid and heating for the local district heating system.

The KNRN order for its plant at Hildesheim includes equipment for sewage sludge reception, conveying, drying including vapor condensation, and incineration with an adiabatic EcoFluid bubbling fluidized bed (BFB) boiler system. The scope of supply also includes a multi-stage flue gas cleaning system, steam turbine, generator, water-steam cycle, and additional auxiliary systems.

Benjamin Klammer, Sales Project Manager, Multifuel Boiler Plant, at ANDRITZ comments, “The feedback from the market and especially our customers shows that we did our job. These contracts prove that we are well prepared for future developments in key market segments that are fully in line with ANDRITZ's corporate strategy and commitment to deliver sustainable technologies and solutions to our customers and support decarbonization, sustainability, and a circular economy.”