There has been a constant improvement in the performance of tissue machines over recent times.

Tissue: an update from ANDRITZ

Based on an interview with Vincent Roy, Director Technical Sales, ANDRITZ Tissue North-America

There is increasing pressure for tissue producers to improve efficiency and reduce energy consumption. ANDRITZ has been busy developing solutions which are innovative, efficient, and minimize the consumption of resources – without compromising on product quality.

Committed to R&D: PrimeLineTIAC – Tissue Innovation and Application Center

With an upward trend in energy prices and other costs, and ever more urgent calls for sustainable solutions throughout the supply chain, tissue producers face plenty of challenges in developing their strategies for the future.

The good news is that growth in the market for tissue is likely to remain quite strong: overall tissue demand looks set to follow global population trends. We would cautiously suggest that the growth rate over the next seven years will remain on a par with, or just below, the average annual rate of 3.6 percent that we have witnessed during the past 20 years. Historically, China has been the fastest growing region in the world by far, and this will most likely remain the case in the years to come.

The Asia Pacific region will probably see growth in away-from-home products, as well as an increase in the production of facial tissues and higher quality/premium bath tissues. Also look out for an upward trajectory in Africa, the Middle East, and Latin America as the people there increase their consumption of tissue products in the years to come.

In North America we are likely to see the effect of tissue consumers becoming more conscious of their environmental impact. But despite higher demand for environmentally friendly tissue products with a reduced CO2 footprint, our tissue experts anticipate a lower overall market growth rate in this mature market in the next seven years.

Committed to R&D

The high level of inflation around the globe is affecting overall costs and equipment lead times for everyone, including us. It also affects our customers’ operating costs and profitability. Nevertheless, we at ANDRITZ are committed to our long-term strategy. Including our pilot machine, we continue to allocate around 10 percent of our tissue segment revenues to R&D and new product development annually, using these state-of-the-art trial facilities as a springboard for innovative developments.

PrimeLineTIAC – our Tissue Innovation and Application Center located in Graz, Austria – is a complete pilot tissue machine used to test, develop, and optimize many different machine configurations and technologies – from conventional dry-crepe through to premium grades such as TAD (Through-Air dried).

PrimeLineTIAC is an excellent tool for ANDRITZ and its customers to develop methods for reducing their overall CO2 footprint by investigating various process inputs and outputs: furnishing (alternative fibers), energy sources (gas, steam, electricity), and fresh water as well as effluent, chemicals, and emissions. What’s more, the PrimeLineTIAC is also a birthplace of Metris, ANDRITZ digital solutions for the tissue industry.

As for R&D and the PrimeLineTIAC, we have various programs in place that involve each of these aspects in one way or another, with the aim of achieving our sustainability targets. Here are some examples: we are investigating and developing ways to optimize water balances and reduce freshwater use, to use effluent emissions, to replace waste streams and turn them into products, and to produce tissue grades with alternative fibers. We are also testing different mechanical methods for reducing thermal drying demand, and improving digitalization to make production more efficient and save resources. We believe that sustainable and resource efficient solutions will continue to be a key area of focus in the coming years as the world’s conscience evolves towards the protection of our environment.

PrimeLineTEX tissue machine for the production of textured tissue with a quality close to premium-structured TAD tissue

Energy reduction

As mentioned before, one of our key contributions is to bring sustainable solutions to the market. Sustainability is an essential part of ANDRITZ's business strategy and our corporate culture, to which all employees are committed. We have defined specific initiatives to steer these important efforts.

As one part of this commitment to sustainability, we have made significant progress in energy reduction in general. The reduction in energy use makes both economic and environmental sense – basically, it is a sustainable strategy in the full sense of the term. With regard to the latter, we have specifically also made significant progress in reducing the use of fossil fuels by developing efficient green energy solutions. Our clear intention is to keep improving in both areas – reducing energy consumption in general as well reducing the use of fossil fuels. Ultimately, our customers need new developments in both of those areas in order to operate more efficiently, especially considering the challenges posed by the global energy supply and the instabilities we all face.

ANDRITZ will therefore remain highly committed to developing technologies that reduce energy costs while also enabling enhanced product quality.

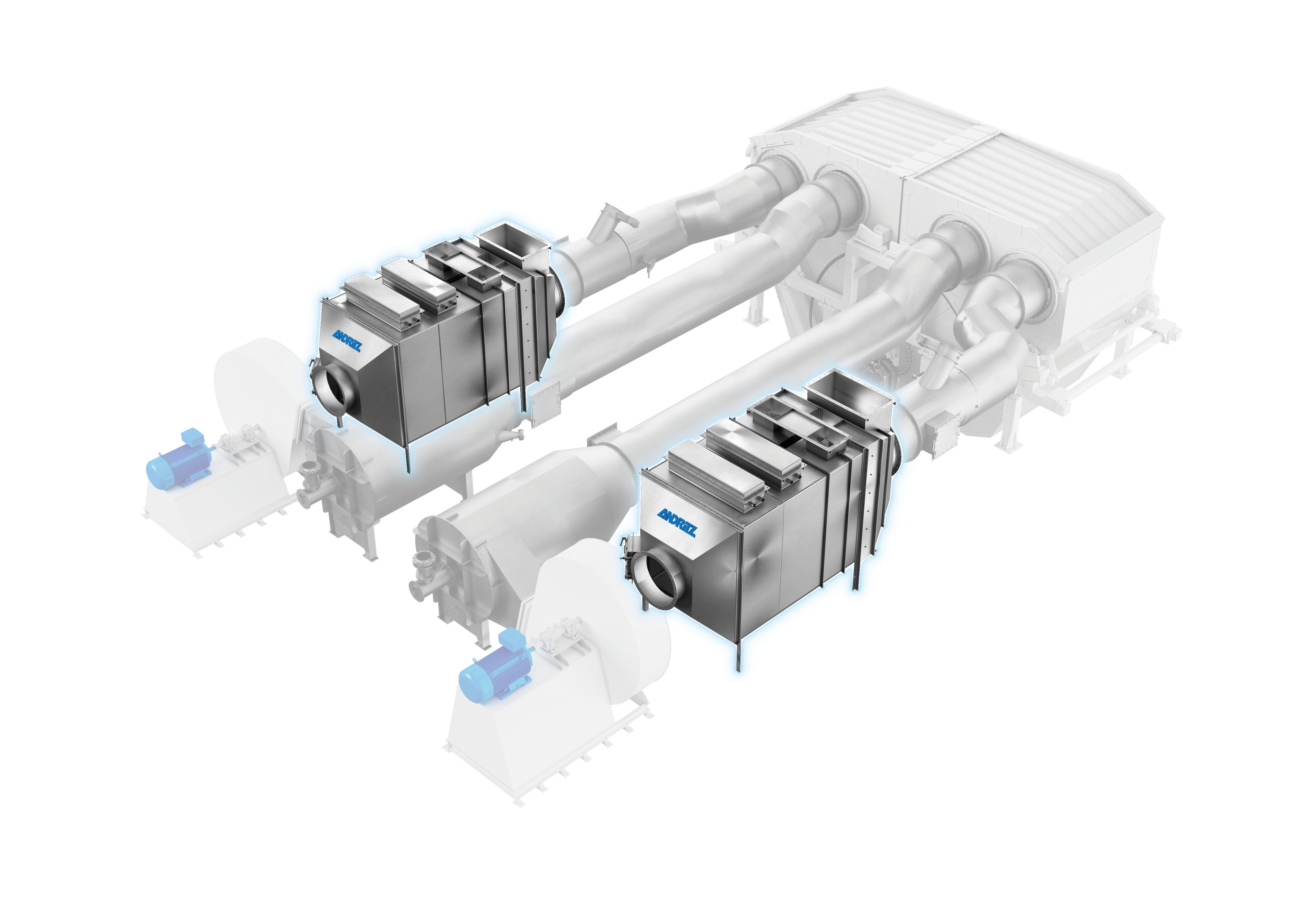

To provide one concrete example for PrimeLineTM, ANDRITZ has optimized its shoe press design and concept. Our PrimePress XT Evo, with its patented loading design that ensures a constant pressure in CD, along with its edge control system and optional cantilevered design, has tangibly helped tissue manufacturers capitalize on energy and fiber savings without sacrificing their OEE (overall equipment effectiveness). In dryness mode, for example, the after-press dryness can increase by up to 6 percent compared to a suction press roll, resulting in thermal energy savings of up to 24 percent. In quality mode, paper bulk is improved, resulting in better paper quality and/or possible fiber savings of up to 10 percent compared to conventional presses. We have recently installed and started up a PrimePress XT Evo fully cantilevered shoe press on a new PrimeLineTM in North America.

As for PrimeLineTAD, ANDRITZ continues to optimize its very successful steel Yankee dryer, thereby demonstrating its capability for TAD applications. At the same time, we continue to investigate advanced dewatering concepts to reduce energy usage in TAD.

PrimePress XT Evo shoe press with patented loading design for energy-efficient drying at high quality

Heating and drying

In terms of heating and drying technology, not only our PrimeLineTM, but also our PrimeLineTAD also offer options that use steam or electric heating technologies for drying, thus significantly lowering CO2 emissions.

Depending on the source of power, electricity can contribute significantly to reducing a mill’s carbon footprint and increasing its energy security. With this in mind, ANDRITZ has introduced the PrimeDry Hood E, which uses the same air system as gas or steam-heated hoods, but with electric heaters to replace the usual gas burners or steam heaters. Needing no combustion air, the PrimeDry Hood E increases energy efficiency for the hood drying system by up to 4 percent compared with gas-heated systems. Electrical heating offers the further advantage that no products of combustion are emitted into the air. Tissue mills can expect the tissue machine to bring a reduction in CO2 emissions of approximately 70 percent – a particular advantage in parts of the world, Europe and the USA included, where mills are subject to limitations or incur costs related to CO2 emissions.

On top of that, ANDRITZ has also developed a patented configuration to retrofit existing gas-fired drying systems with a hybrid method that combines gas and electric heating, allowing a mill to switch to the preferred option depending on the cost and availability of the energy source during a specific operating period. This gives a mill utmost flexibility with regard to reducing drying costs, saving energy, and reducing emissions.

Looking ahead, we intend to optimize the latter developments while pushing innovative technologies even further. For example, we are cooperating with a customer and our equipment partners in Europe on a project to generate high-pressure steam for a large Yankee and steam-heated hood using a boiler with biomass as fuel, thus resulting in an almost fossil-free thermal energy system. The biomass is used to generate syngas (fossil-free fuel), which will feed a specially-developed syngas Yankee hood burner. This comes at just the right time, as mills are seeking options to replace LPG or natural gas in tissue dryers with an alternative solution that reduces CO2 emissions, to cut operating costs, or to improve fuel availability. Last but not least, ANDRITZ is also working on advanced hot air exhaust recirculation systems to lower the amount of energy that is wasted and transferred to the atmosphere.

Efficiency and health and safety matters

An outstanding example of increased efficiency is provided by the ANDRITZ PrimeTurnUp system, our full-width single-wrap turn-up system, which achieves an efficiency of 99 percent or more while eliminating dust contamination. The PrimeTurnUp system contributes significantly to increasing production while reducing emissions.

As health and safety is so important these days, we have also developed and installed many other components and solutions in that regard, including high-performance dust removal systems to improve machine and machine room cleanliness, reduce sheet breaks and machine maintenance, increase machine operating efficiency, and preserve the personal health of operating personal.

Last but not least, coming back to the topic of increased efficiency, we intend to continue to expand in the area of industrial automation and digitalization products and services, specifically those under our Metris brand.

PrimeDry Hood E electrically heated Yankee hood for sustainable tissue production

What does the future hold?

Since the COVID-19 pandemic, the world has evolved at a quicker pace in terms of technology. We believe that the progress in the development of artificial intelligence (AI) technologies will help to maximize overall production by enhancing troubleshooting capabilities. By unlocking data and using thorough algorithms, knowledge gained from one area of the process can typically also be applied to optimize overall machine performance.

The operator no longer needs a deep understanding of the machine, since adjustment recommendations can be made live on the DCS or another device in the control room. Even a new, unskilled operator can now run a tissue machine without needing any knowledge of appropriate machine parameters. In view of the global labor shortage and high turnover rates in plants, AI, together with cyber security and condition monitoring with smart sensors in an integrated approach, or the digitalization of the entire process, will be critical areas of development for tissue manufacturers and OEMs. ANDRITZ has made significant progress in machine automation and remote assistance (remOT), mainly via our Metris Performance Centers, which help to improve the OEE of tissue producers on the paper machine and when converting jumbo rolls.

The global upwards trend in the cost of energy will also push tissue manufacturers to select different types of machine concepts to achieve their desired tissue quality, depending on the region in which they operate. For example, ANDRITZ PrimeLineTEX technology, which is optimized to make products close to structured tissue using advanced dewatering and drying technologies, will allow tissue manufacturers globally to continue to produce structured tissue without incurring the high energy costs that are typical of a conventional TAD machine concept.

This is just one of many examples of flexible and reliable solutions from ANDRITZ which allow products and processes to meet sustainability goals while still giving the final customer the quality and experience they expect.