Reutlingen, Germany, September 2022. Conservation of resources, reduction of energy consumption, CO₂ reduction, closed-loop circular economy - these are all firmly established cornerstones of ANDRITZ's sustainability strategy.

UPM and ANDRITZ: Cooperation project in circular economy for used Forming Fabrics and Press Felts started.

ESG (Environmental, Social, and Governance) goals have become increasingly important for companies in various industries. Resource- and energy efficiency, reduction of CO₂ emissions and promoting circularity – these are all firmly established cornerstones of UPM's and ANDRITZ's sustainability strategy.

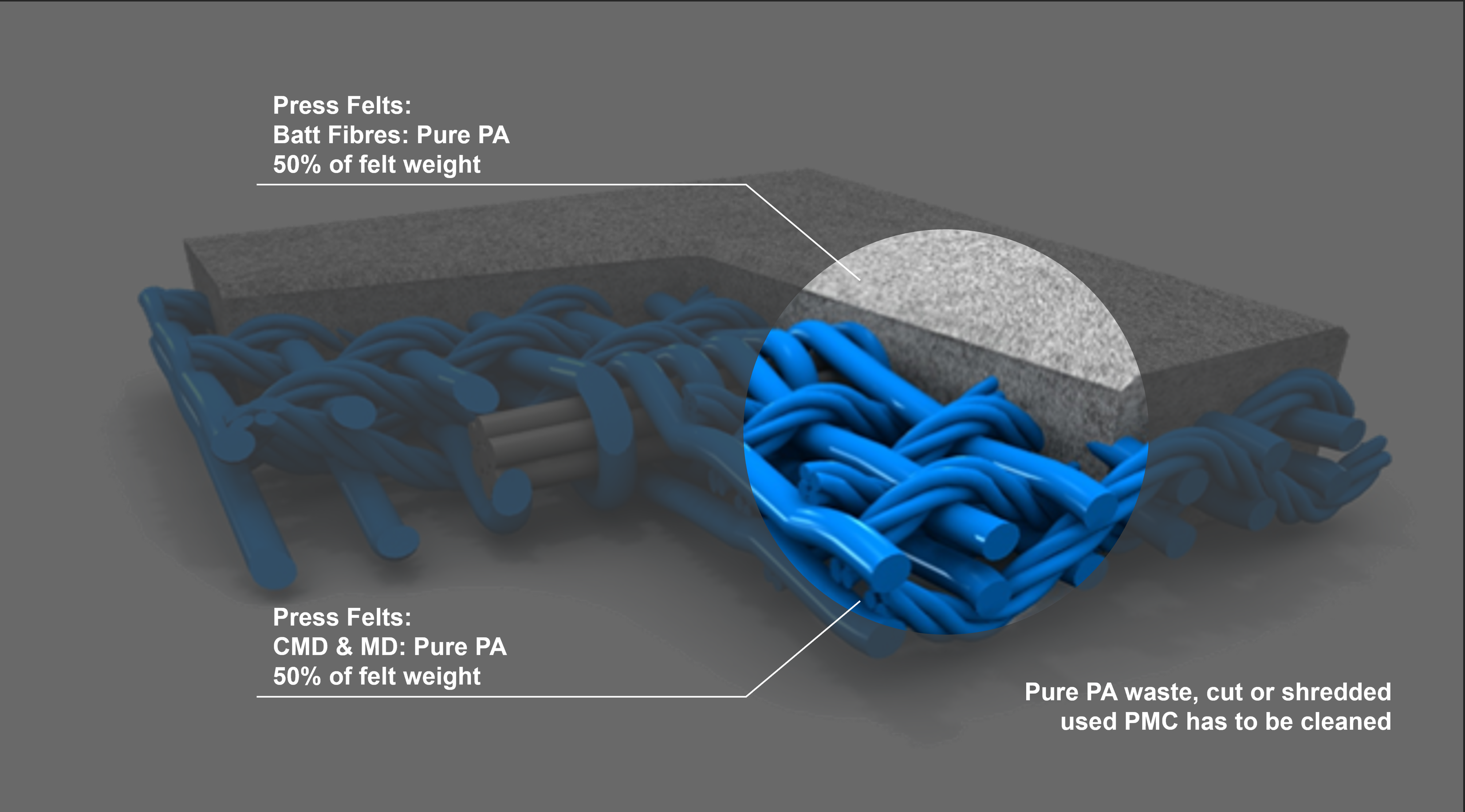

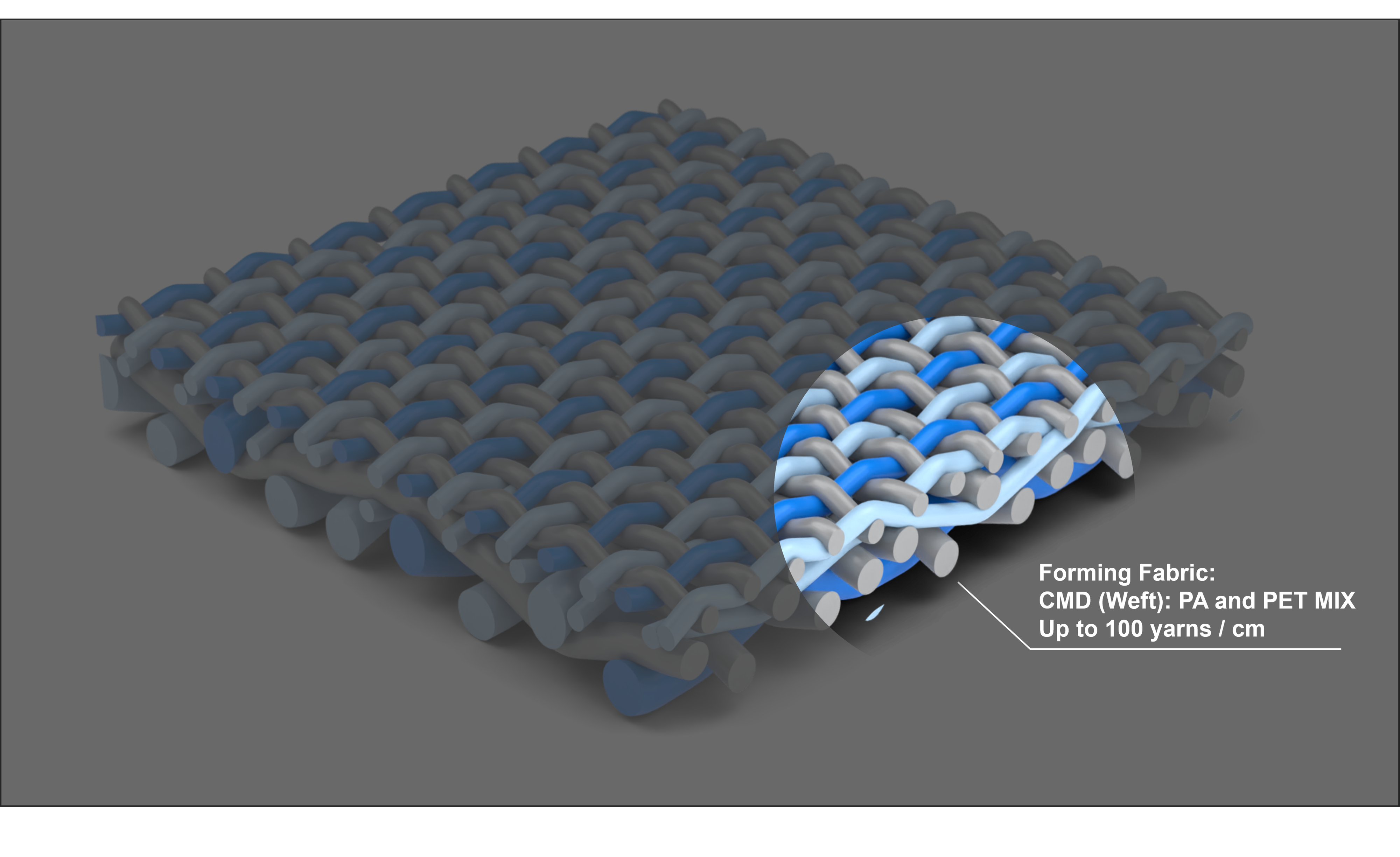

ANDRITZ is pursuing its next recycling research project in Paper Machine Clothing (PMC) together with UPM. The recycling project covers the recycling of forming fabrics and press felts made of polyamide (PA) and polyethylene terephthalate (PET). The main objective of the new research project, which is funded by FFG (Bridge2 funding program no. 895423) following the EU Green Deal and Waste Framework Directive 2008/98, is the research and development aiming for a carbon neutral material cycle.

From the transportation of used PMC from the paper mills to the subsequent recycling processes, including cleaning and separation of PA and PET, to the subsequent reuse of the recycled material to produce new monofilaments and the manufacture of new paper machine clothing, a continuous, closed-loop, resource- and energy-saving cycle is to be created. In the long term, the current thermal disposal of material waste, which is associated with high CO₂ emissions, will be reduced significantly.

The joint project between ANDRITZ and UPM started in 2022, and after the Paper Machine Clothing (PMC) recycling technology has been proven in smaller companies, it has been agreed to implement recycling processes at four of UPM's main production sites in Europe. The scope of the project will include not only the recycling of used polymers, but also logistics and regulatory topics. This project has the potential to revolutionize the way PMCs and pulp and paper producers will work together in the future.

The cooperation between ANDRITZ and UPM demonstrates clearly how companies can work together to find innovative solutions to sustainability challenges and reduce environmental impact while creating economic value. This collaboration also underlines the commitment of both companies to sustainable and responsible operations, as it is an integral part of ANDRITZ's ESG strategy.