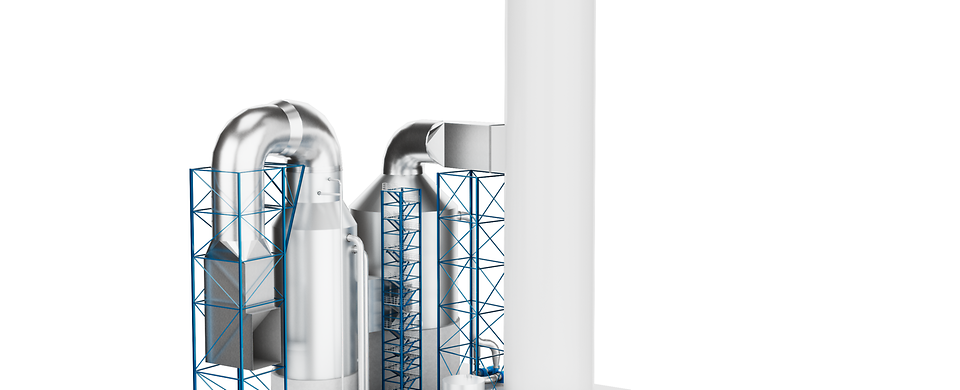

The key features of the ANDRITZ DeNOx scrubber are:

- NOx removal rates up to 80%

- Low temperature application (< 100°C possible)

- Simultaneous dust and SO2 removal

- Reliable operation for harsh operational conditions (temperature, flue gases with various contaminants, …)

- Integrated heat recovery with GGHs or feed water pre-heating