ANDRITZ Hydro in Linz, Austria operates mainly in the large hydro, service and rehab, and compact hydro sectors.

Hydraulic test rig in Linz

In view of the large number of test rigs, the performance strength of the test rigs, and the specific know-how of the employees there, Linz is the most important ANDRITZ Hydro location in terms of hydraulic development.

The hydraulic test rig in Linz has been in service since 1968 and is currently the largest location for research and development within ANDRITZ Hydro.

Test rig

The know-how generated at the test rig in Linz provides the basis for continuous development and improvement of the operating behavior of hydraulic machines.

The test rig today

Tests for pumps, as well as for axial, radial, pump, and Straflo turbines, can be performed on five test rigs. Axial models with a horizontal shaft arrangement can also be tested at the bulb test rig. Hydraulic conditions of the prototype turbine, such as net head, water discharge, and cavitation, are simulated in a closed water loop. The test results are used to analyze and display the complete operating range of the turbine models in order to attain optimum efficiency.

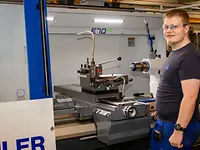

At the test rig in Linz, well over 50 employees are involved in CFD, model design, model assembling and disassembling, planning and execution of tests, evaluation and reporting, and field tests.

The test rig in the past

When Baldwin-Lima-Hamilton (BLH) withdrew from the turbine business at the end of the 1960s, the VOEST turbine division needed to set up a test rig in order to guarantee continuous further development of the hydraulic know-how.

Hence, the first test rig was built in a former repair workshop for locomotive engines in 1968. In 1974, extension work began by adding other rigs, with the fifth rig – named “Tanja” – being inaugurated in 2006.