Africa

Tidal Energy

The future of ocean-based electrical energy production has begun

About 70% of our planet is covered with water, but only 3% of this is fresh water. The far larger amount of 97% of salt water possesses a huge potential of sustainable and clean energy. After a century of developing fresh water resources like rivers and lakes from the mountains to their deltas, now mankind is starting to produce electrical energy direct from the ocean. Amongst numerous technical approaches, today tidal power is considered to be one of the most promising additional future energy sources, with an estimated worldwide potential of more than 150,000 GWh.

Ocean energy future: 1- very low head, 2 - tidal, 3 - tidal current, 4 - tidal lagoon

Hydropower in transition – Very low head, barrages and lagoons

The history of hydropower technology development has followed the rivers - from high head solutions to very low head hydropower plants. As a leading global supplier in hydropower, today ANDRITZ HYDRO is also a pioneer in providing commercial equipment for the ocean-based electrical energy future.

2012 – Very low head hydropower plant

ANDRITZ HYDRO has followed this development and realized several very low head examples like the world’s largest HYDROMATRIXTM power plant Ashta, Albania, only 30 km from the coast.

2011/2014 – Tidal power plant

Tidal power plants are saltwater applications and typically use an existing natural bay blocked with a dam. In 2012 the world largest tidal power plant Sihwa (10 x 26 MW) was inaugurated in South Korea. ANDRITZ HYDRO delivered and installed the electromechanical equipment. In 2014, ANDRITZ HYDRO was awarded with the rehabilitation of the oldest commercial tidal power plant HPP La Rance in France.

2014 – Tidal current power plant

At the end of 2014, ANDRITZ HYDRO Hammerfest received an order from the UK-based tidal development company MeyGen Ltd. to supply three 1.5 MW tidal current turbines for an array under construction in the Inner Sound of the Pentland Firth, Scotland.

2015 – Tidal lagoon power plant

The latest tidal energy design is to build an arteficial off-shore lagoon, mostly encompassed by a dam providing a head. In February 2015 ANDRITZ HYDRO, as a market leader in tidal energy technology, was appointed in a consortium with GE by Tidal Lagoon Swansea Bay plc. as preferred bidder for the supply of the electromechanical equipment for the world’s first tidal lagoon hydropower project in Swansea Bay, Wales, UK. It will be located in the Severn Estuary and will be equipped with 16 bulb units, more than 20 MW each.

The future of ocean-based electrical energy production has begun

Tidal currents

To use the unexploited energy from tidal currents ANDRITZ HYDRO integrated one of the world’s leading companies in the development and supply of tidal current turbines beneath the sea level – today known as ANDRITZ HYDRO Hammerfest. Established in 1997 by the local utility company Hammerfest Energi, ANDRITZ HYDRO Hammerfest has offices in Hammerfest, Norway and Glasgow, Scotland.

Tidal current turbines – technology and challenges

Tidal power is clean, renewable, reliable, and predictable. Any visual or audible impact above the surface is eliminated and normal shipping traffic will not be affected by the presence of fully submerged tidal arrays. It is based on experience of the technologies and solutions used in hydropower, marine propulsion, wind energy, offshore oil and gas industries, with focus on reliable and sustainable solutions.

The tidal turbines are designed to generate electrical energy from water currents with a speed above 1 m/s and at depths between 35 and 100 m. They are deployed on the seabed and kept in position by gravity, pins or pilings, depending on the seabed and tidal stream characteristics. Moreover, the horizontal axis turbines are equipped with a specially-designed variable-speed pitching mechanism and a nacelle yawing system, allowing the optimal harnessing of tidal currents in both ebb and flood directions. The whole substructure is designed to have a very small footprint, while the nacelle is optimized to minimize its drag profile.

Although ocean currents move slowly relative to typical wind speeds, they carry a great deal of energy.

For the same rotor swept area, water moving at 2.5 m/s exerts about the equivalent amount of force as a constant wind speed of above 100 km/h (27.8 m/s). The tide level can be predicted well into the future, thus the speed of associated tidal currents can also be predicted with high accuracy.

Alongside the advantages of power generation from tidal flows, there are considerable technical challenges associated with this new technology. For example, a challenge is posed by the high turbulence levels and large waves associated with storms originating in the ocean. At a rotor hub height even 20 m below the surface, the effect of such large waves is to impose a sinusoidal velocity component with a magnitude of around 4 m/s. Considering a normal cut-out water flow speed of 4.6 m/s, this wave results in a requirement for the turbine being designed to survive in flow speeds twice as high as the cut-out speed. Adding the requirement to consider fault conditions, which may result in pitch or yaw system misalignments, the thrust loading on the rotor hub can be up to 1,500 kN (150 tons), which is five times higher than the mean operating value of 340 kN (34 tons).

An 18 m rotor gives the turbine a swept area of 255 m2. During extreme loading events the bending moment at the root of each of the three turbine blades can be up to 2,700 kNm. The peak rotational speed during normal operation is 14.5 rpm, giving a tip speed ratio of 4.8 – the ratio between the tangential speed of the tip of the rotor blade and the actual tidal current velocity. This high tip speed ratio is related to efficiency, with the optimum varying with the blade design. It results in a requirement for strong blades due to large centrifugal forces.

The MeyGen tidal current project

At the end of 2014, ANDRITZ HYDRO Hammerfest received an order from UK-based tidal development company MeyGen Ltd. to supply three 1.5 MW tidal current turbines for the array in the Inner Sound of the Pentland Firth, Scotland.

The Inner Sound of Pentland Firth is recognized as one of the most challenging and highly active sites of tidal flow with high wave frequency and requires careful engineering, manufacturing, and assembly to ensure that the technology deployed is able to operate and perform within its environs.

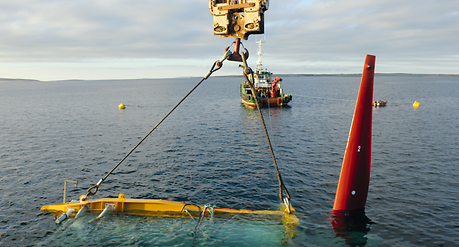

This order follows the successful completion of a series of tests with the pre-commercial prototype tidal current turbine HS1000 at the European Marine Energy Center (EMEC) in Orkney, Scotland. Furthermore, it is the first commercial order worldwide for the supply of large-scale tidal current turbines and forms part of the first phase of the project.

Offshore design codes state that any structure should be designed for storm conditions with a return period of at least twice the intended life of the structure. In the case of the MeyGen project, this means designing for a wave with a return period of 50 years, in theory a wave as high as 16 m.

All major tidal turbine components are designed by ANDRITZ HYDRO Hammerfest in close cooperation with ANDRITZ HYDRO. The major components of the turbines like rotor blades, hub and front plate including the main bearing system, main-shaft, pitch and yaw system as well as assembling and test of the turbines prior to transportation to the site for deployment are supplied by ANDRITZ HYDRO Ravensburg, Germany. Engineering, design and delivery of electrical as well as control and instrumentation components are provided by ANDRITZ HYDRO Vienna, Austria.

In the long-term, MeyGen is planning to install 269 turbines with an overall capacity of 398 MW to provide predictable, renewable, and sustainable energy for about 175,000 Scottish households.

The average generation per turbine is expected with 4.4 GWh per year.

Installation of HS1000 at EMEC

TECHNICAL DATA

MeyGen | |

| Type: | Mk1 |

| Output: | 3 x 1.5 MW |