Renewable hydropower for growing energy needs - Lao PDR, Luang Prabang

Testing for the best

Operating the world’s most powerful R&D test rig

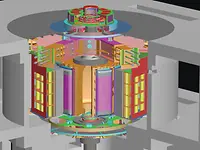

After a planned construction time of about a year, the new high-performance test rig in Linz, Austria, has been inaugurated. This new ANDRITZ test rig is the most powerful universal test rig in the world and the inauguration marks a new milestone in R&D history. It is able to test any turbine type from a low head bulb unit up to high head multi-stage pumps.

The launch of the new test facility took place at the beginning of March 2023 with an employee celebration in the presence of Wolfgang Semper, former member of the Management Board of ANDRITZ HYDRO GmbH and member of the Executive Board of ANDRITZ AG.

In the future it will be possible to test model turbines for hydropower plants with a particularly high head of up to 250 m and a maximum flow rate of 1.8 m3 / s. Meeting the very highest standards, it will also be possible to implement special customer requests regarding larger models and extended test conditions. Test rig operations will be supported by the ANDRITZ all-in-one Metris platform, which will be used as a framework for the automation. The high-performance test rig was designed as a universal test rig for Kaplan turbines, Francis turbines, storage pumps and pump turbines. It is able to assess these designs across a broad range of conditions from low to high head, and in both vertical and horizontal arrangements.

Immediately after the inauguration ceremony, the high-performance test rig was put into commercial operation and is already providing test-specific spectra for different customers, as well as internal R&D requirements for model testing. Directly after the festivities concluded, a reference test setup was changed to a specific customer project, which had a very large model inlet structure and a bigger-than-standard model size. This large size was established under the terms of the contract, and the customer’s request also ended up with a higher-than-standard Reynolds number* for the testing conditions.

Precision at work. Specialists are overseeing the tests in the new test rig.

Official inauguration of the high-performance test rig in Linz, Austria

Despite challenges due to supply chain issues during the COVID pandemic, the team was able to successfully commission the test rig. The facility thus achieves all the required performance metrics and meets the very high expectations that were set out internally. We are proud that we can offer these new capabilities to clients, bringing additional capacity to our worldwide laboratories and increasing the physical size of possible testing ranges.

As one of the world's major turbine manufacturers, ANDRITZ considers it vital to maintain a leadership role in research and development. This substantial investment once again illustrates ANDRITZ’ on-going commitment to that goal, particularly in areas related to key markets such as pumps and pump turbines.

Performance Data

- Maximum testing head: 250 m

- Maximum discharge: 1.8 m3 / s

- Maximum testing power: 1.3 MW

- Maximum torque: 8,500 Nm

Fully compliant with the relevant IEC standard, 60193 Hydraulic turbines, storage pumps and pump-turbines

*Reynolds number:

The Reynolds number is a dimensionless ratio named after the physicist Osborne Reynolds, used for fluid mechanics.

Author: Sigrun Fugger