Italy, Camaioni

Langenprozelten, Germany

A contract for the refurbishment of the world’s most powerful single-phase hydropower motor generators at pumped storage power plant Langenprozelten has been awarded to ANDRITZ HYDRO by German-based Donau Wasserkraft AG (DWK), a subsidiary of Rhein-Main-Donau AG (99.25%) and Uniper (0.75%).

Pumped storage plant Langenprozelten is situated in the Unterfranken region in the German federal state of Bavaria.

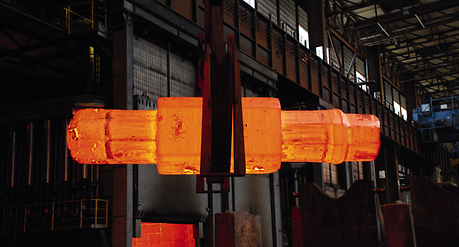

Red-hot shaft on its way to the forge process

With an output of 2 × 94 MVA, Langenprozelten is Deutsche Bahn’s primary peak-load power plant, providing sufficient electrical energy to sustain 50 InterCity trains travelling at 200 km/h.

Single-phase generators are specifically designed for the railway’s 16.7 Hz traction power network. The extreme forces acting on the motor generator’s rotor require not only particularly precise calculations, but also special experience in selecting the proper materials.

Only a few forges in the world are able to manufacture with flawless quality the required forged shaft with a gross weight of about 170 tons.

The high mechanical stress exerted on the poles - each weighing a world record breaking 34,000 kg - joints that link the damper bars to the damper ring segments. The damping system was designed specifically to handle the high currents (34,000 A ring current!), mechanical stress and extensive thermal expansion. Comprehensive tests, such as centrifugal force tests monitored with a high-speed camera, were performed on all damping system components to verify the calculation results. At the ANDRITZ HYDRO balancing tunnel testing facilities, the entire rotor was tested at the run-away speed of 756 rpm. During the test, each pole on the rotor had to be held with a force equivalent to 27,000 tons, which corresponds to the weight of 70 fully loaded Boeing 747 aircrafts.

Assembly at the facility required extreme precision and the know-how of experienced engineers. Since the power plant’s crane was designed for a maximum load of only 110 tons, the two-part stator housing had to be assembled inside the generator annulus space before the stator lamination was stacked and the winding inserted. The rotor has to be assembled inside the stator as well.

The project is in now nearing the recommissioning phase.

34 t pole for the generator

TECHNICAL DATA

| 2 single-phase synchronous motor generators (vertical) | |

| Output | 94 MW |

| Voltage | 10.75 kV |

| Stator current | 8,744 A |

| Damper current | 34,000 A |

| Speed (2 rotational directions) | 501 rpm |

| Shaft-generators for station supply (on a common shaft) | |

| Output (three phase) | 1,260 kVA |

| Voltage | 400 V |

| Runner diameter | 1150 mm |