Find the right products for your needs from ANDRITZ Feed and Biofuel

Pocket feeder

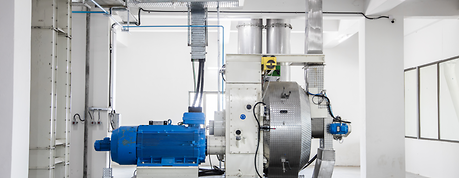

The hammer mill is a critical component of most feed manufacturing operations. Its performance and reliability can be optimized only if it receives a steady, consistent, uniform supply of material across the full intake area of the hammer mill.

It also requires an auto-control drive system that automatically adjusts the speed of the feeder for quick, accurate, feed-rate control according to the hammer mill's optimal performance capability.

The most common hammer mill feeding devices include:

- Screw feeders

- Rotary feeders, including conventional, multiple-vane, pocket rotary feeders. This grinding feeder system provides smooth, consistent discharge.

The Pocket feeder design

In this design, the rotary cylinder consists of material receptacles that are divided and staggered across the width of the feeder, creating a larger number of pockets. This provides many discharge points during the rotation of the feeder. The result is a more even feed rate and more even distribution of material across the full width of the mill intake, preventing the formation of slugs.

Another benefit of the pocket feeder design relates to the shape of the rotary feeder’s material receptacle. A round-bottom cup with no corners or sharp angles provides more effective discharge for a wide range of raw materials.

Automatic control system

The pocket feeder should be installed with a variable-speed drive. The purpose of this drive is to communicate the load or amperage of the hammer mill's main drive motor to the feeder motor to adjust the feeder speed. This will ensure that the feeder does not supply the mill with more material than the hammer mill's main drive motor can tolerate. With the capability of constant adjustment through the feeder’s variable-speed drive, it is possible to avoid overloading the mill.