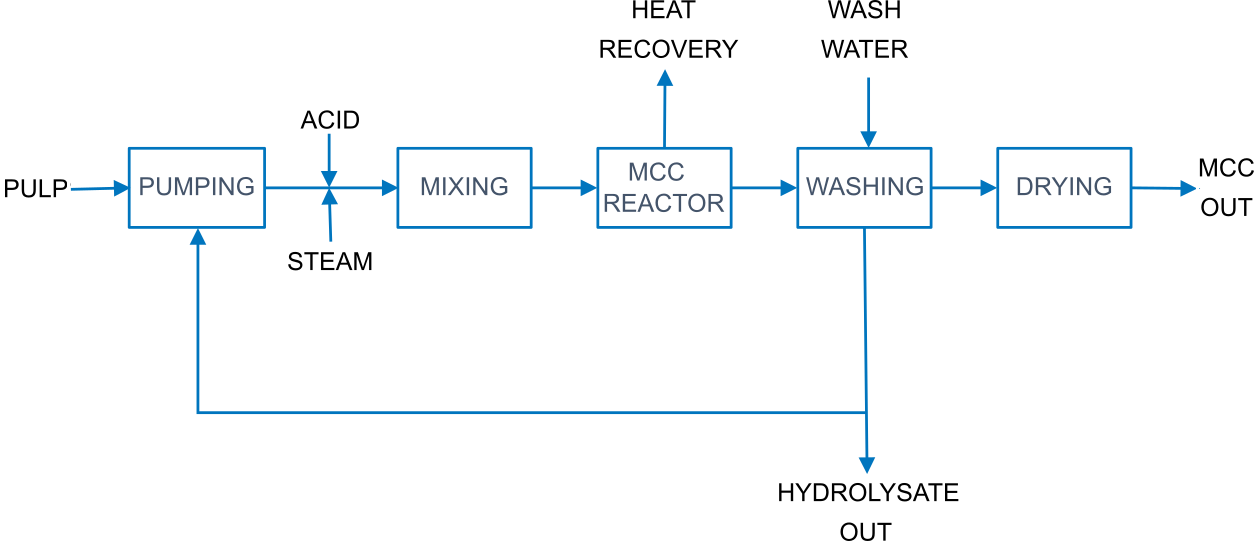

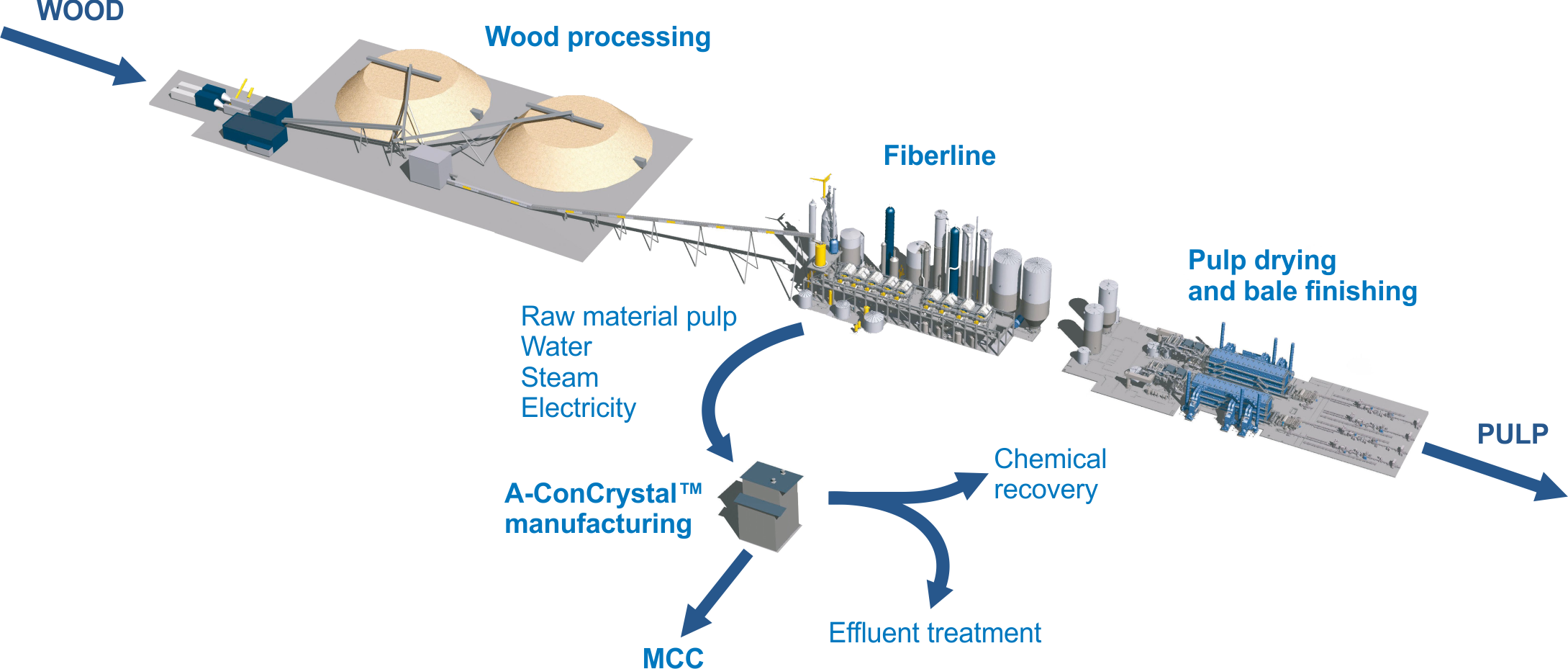

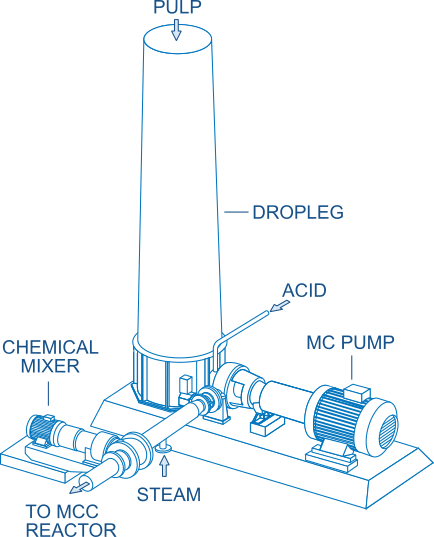

Microcrystalline cellulose (MCC) is purified and partially depolymerized cellulose obtained by treating alpha cellulose with mineral acids. It was originally developed in the 1950s in a search for a stronger rayon thread. Unfortunately, high production costs have restricted its use for decades, and although it is widely used in many applications in a variety of industries, the high cost is still a significant hindrance for potential users.

Digital service and support for tissue, paper and board mills worldwide The PrimeLinePerformance Center is an impressive milestone for ANDRITZ in the area of digitalization and Industrial Internet of Things (IIoT) solutions. Tissue, paper, and board mills are able to benefit from individual and fast customer service by using the ANDRITZ Metris platform for the optimization of production processes, operator trouble shooting and decision support.