Disc filter services

ANDRITZ offers disc filter services and upgrade solutions for all disc filters, regardless of the original manufacturer.

Experience of decades in disc filter design and manufacturing and the combined expertise of engineers from ANDRITZ, Ahlstrom, Impco, and Hedemora give ANDRITZ a definite advantage when upgrading your disc filter.

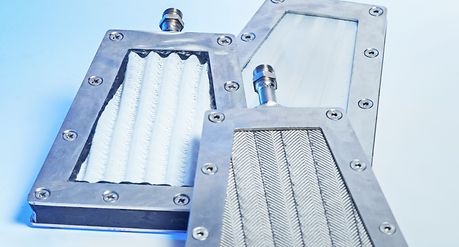

Disc filter sectors

Disc filter upgrades

There are various options for optimizing filter operation, reducing operating problems (such as plugging of filters or variations in consistency or filter vat level), increasing production capacity, or improving filtrate quality. ANDRITZ provides upgrades for each type of disc filter, no matter who the original equipment manufacturer was.

Innovative upgrade solutions are available for ...

- Disc filter sectors: proven ANDRITZ SuperFlow construction for all types of sectors - ANDRITZ and other OEM designs.

- Center shaft: ANDRITZ design to achieve higher throughput combined with minimum flow losses.

- Filtrate valves: optimized solutions for ANDRITZ disc filters and various other brands.

- Knock-off and cleaning system; shaft seal; disc stabilization; repulper.

Disc filter center shaft

Disc filter services

On-site sector rebagging and disc filter maintenance

The ANDRITZ Disc Filter Service Box (which is based in our Levice, Slovakia facility) comes right to your mill. It is a compact unit staffed with ANDRITZ technicians who can repair or replace bags or wear parts. The unit contains all equipment and tools needed. All we need at the mill is a workshop location, water, and electricity – and we'll be on site whenever your shutdown is scheduled.

ANDRITZ disc filter improvement survey

ANDRITZ specialists identify areas for process and product improvement (capacity and/or filtrate quality) and make recommendations to achieve the best results.

ANDRITZ Leaf Tester

ANDITZ can provide on-site disc filter tests for comparative evaluation of various filter types (sector designs, bag fabrics) and process parameters. Based on the analysis of stock samples collected directly at the customer's disc filter under real operating conditions, the improvement potential can be determined.

ANDRITZ Leaf Tester: On-site comparison of disc filter sectors and bags