Dramatically reduce your power consumption in screw press operation

Screw press service

Solutions from a global leader in dewatering technologies

The in-depth knowledge of dewatering machines and processes that ANDRITZ has gathered in the past 70 years form the basis of our service expertise and have enhanced the development of innovative service products for pulp screw presses.

Service range

- High-quality spare parts and engineered wear products

- Customer-specific maintenance and inspections

- On-site services for shaft welding and grinding

- Innovative solutions for screw press upgrades, such as ...

- the ANDRITZ Low-energy concept [Read more]

- opportunities for boosting production to benchmark levels [Read more]

- solutions for a considerable increase in outlet dryness [Read more]

These services can be provided for all pulp screw presses, no matter who the original equipment manufacturer (OEM) was.

Improvement of key components

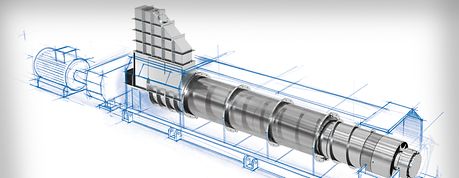

For optimized performance of your screw press it’s worth taking a closer look at the individual s components to identify their improvement potential. The overall objective is always to increase the productivity of your press, while improving energy efficiency and reducing maintenance issues.

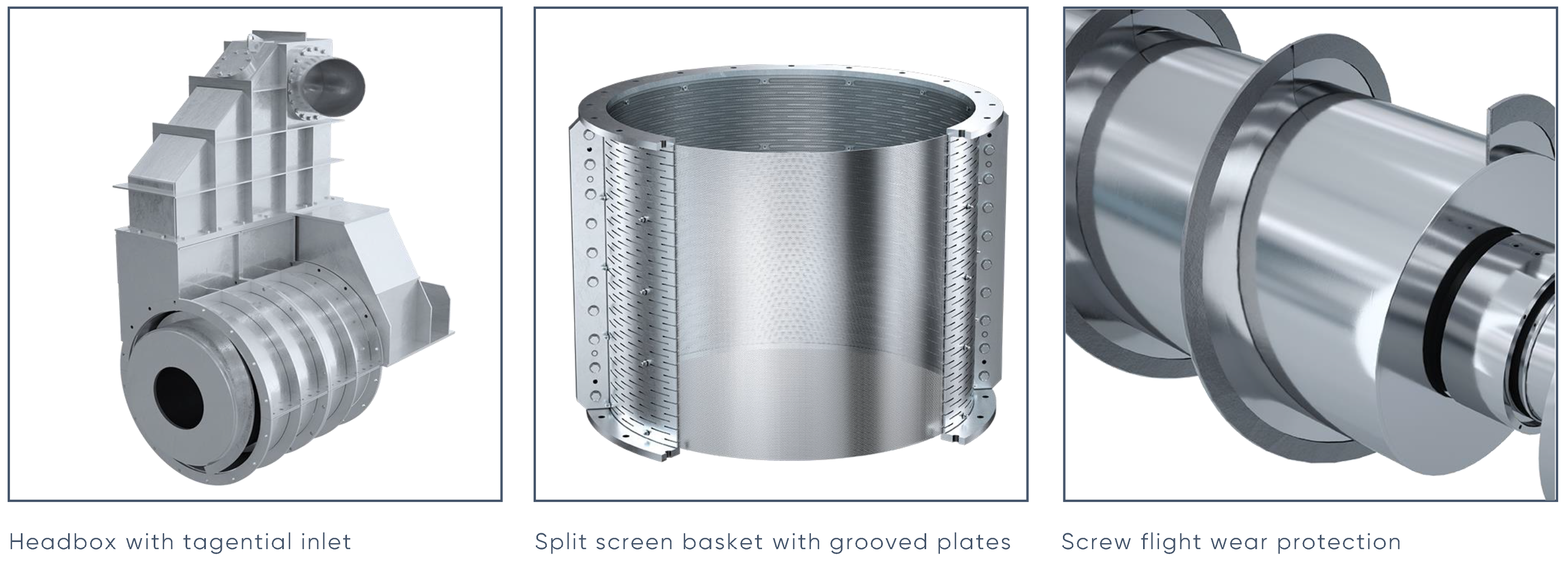

- Headbox – for even feeding and smooth operation

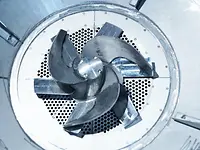

- Screw shaft design and geometry – for stable operation and increased efficiency

- Durable screw flight protection – for consistent dewatering performance

- Screen baskets and plates – for optimized dewatering behavior

- Simple and rigid counter-pressure system – for constant and high outlet dryness due to its adjustable design

- State-of-the-art screw press control system – for smooth operation at maximum throughput