REDUCTION OF TOTAL COST OF OWNERSHIP

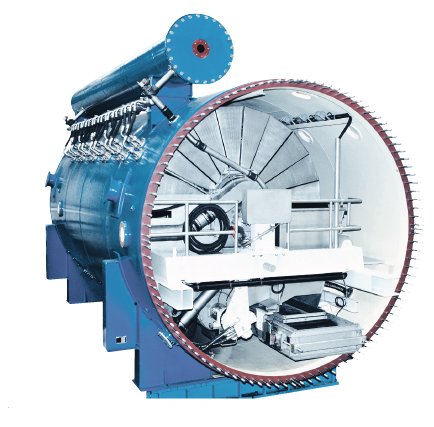

The ANDRITZ hyperbaric disc filter is a very competitive technology for filtration requiring high throughputs as the cost per ton will be less compared to other equipment for high tonnages. Customers can save up to 50% of the total cost of ownership thanks to:

- Lower filter cloth consumption

- Fully automated and continuous operation

- Highest specific throughput generated thanks to the high-pressure system

- Small footprint as less space is required for a large filter area

LOWEST RESIDUAL MOISTURE

Moisture content is an important key parameter in many processes. Thanks to the high pressure differential of up to 5.8 bar, the ANDRITZ hyperbaric disc filter can obtain a low residual moisture and thus meets process requirements and save transportation costs because of the reduced weight.

CLEAR FILTRATE

The ANDRITZ hyperbaric disc filter generates a clear filtrate, thus avoiding accumulation of fine particles in the process water circuit and optimizing water recirculation in the system.