Chemicals

Plastic intermediates (e.g. BPA, PTA, PET, melamine, etc.), dyestuff, beneficiation pigments (e.g. iron oxides, titanium dioxide), soda, pharmaceuticals

The Krauss-Maffei pressure drum filter TDF comes in a closed design, which allows processing of toxic products under inert gas. When conventional methods have to pass or are insufficient, our pressure drum filters are the right choice to meet your separation requirements efficiently and reliably. Operation at pressures of up to 10 bar and temperatures of up to 200 °C are thus no obstacle anymore.

Krauss-Maffei pressure drum filter TDF open

Krauss-Maffei pressure drum filter TDF inside view

|

|

Plastic intermediates (e.g. BPA, PTA, PET, melamine, etc.), dyestuff, beneficiation pigments (e.g. iron oxides, titanium dioxide), soda, pharmaceuticals

Starch

Proteins

Coffee

Coal preparation

Iron ore

| Average particle size | 1-300 µm |

| Filtration capacity | 1,000-10,000 l/m2h |

| Solids throughput | up to 9,000 kg/m2h |

| Pressure operation | up to 10 bar |

| Operating temperature | up to 200 °C |

The suspension to be filtered is fed continuously to the filter trough. Depending on the application, different systems are available to guarantee homogeneous mixing of the slurry. Thanks to the specially designed pendulum agitator from ANDRITZ SEPARATION, sedimentation of the solids is prevented.

The shell of the filter drum is divided into cells and covered by a filter cloth. Approximately 30% of the filtration area is submerged in the suspension and the drum rotates at up to 6 rpm.

The Krauss-Maffei pressure drum filter TDF operates with overpressure inside the pressure vessel, forcing the liquid to filter through the filter cloth. Inside the control head, the drum surface is divided into different process steps: cake formation, cake washing, demoisturizing, discharge, and cloth washing. In the course of one revolution, each point of the drum area passes through these zones in succession. The filtrate drains off through hydraulically optimized suction cells, filtrate pipes, control head, and separator.

The filtered solids layer emerges from the slurry as the drum rotates and is then washed, dried, and removed from the filter cloth. The wash liquid is applied to the cake either directly by washing devices (weirs, spray nozzles) or through a wash belt placed on top of the solids layer.

The filtrates from the washing zones can be drained off separately, enabling multi-step counter-current washing. The filter cake is discharged by means of a discharge device covering the entire drum width and which is specially suited to the cake thickness, consistency, structure, etc. (scraper, roller).

As the drum rotates, it is re-immersed in the suspension. The filter cloth can be cleaned before the next filtration cycle, either with water jets or with bubbles.

If the pressure level in the connecting process steps is different to the operating pressure of the Krauss-Maffei pressure drum filter TDF, a rotary valve is used for equalization.

Discharge design options

| Technical Data | Model | TDF 9.2 | TDF 13.1 | TDF 20.9 | TDF 26.2 |

| Filter area | [m^2] | 0.72-4.3 | 6.0-12.0 | 16.0-26.0 | 29.0-41.0 |

| Drum diameter | [mm] | 920 | 1,310 | 2,090 | 2,620 |

| Drum width | [mm] | 250-1,500 | 1,500-3,000 | 1,500-4,000 | 3,500-5,000 |

| Number of cells | [-] | 20 | 20 | 24 | 24 |

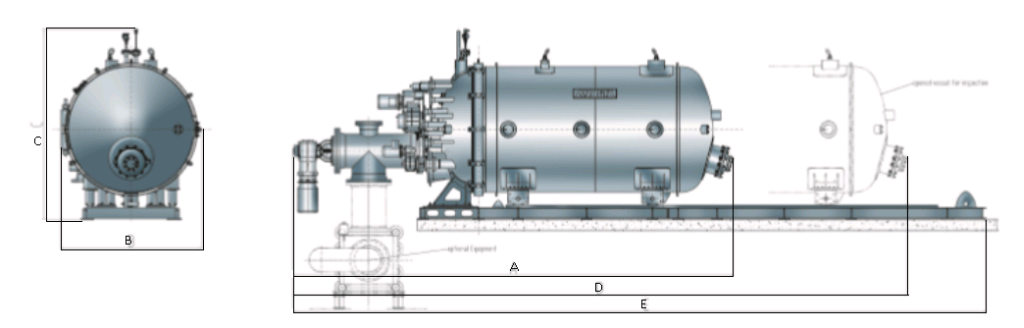

| A | [mm] | 3,200-4,550 | 6,550-8,050 | 8,350-9,850 | 10,400-11,900 |

| B | [mm] | 2,300 | 2,575 | 3,600 | 4,650 |

| C | [mm] | 2,650 | 3,475 | 4,350 | 5,375 |

| D | [mm] | 4,750-6,000 | 9,700-11,200 | 12,750-14,250 | 14,900-16,400 |

| E | [mm] | 5,100-6,350 | 11,150-12,650 | 14,275-15,775 | 16,300-17,800 |

| Weight (without product) | [t] | 6.35-7.5 | 13.5-22.0 | 32.8-36.5 | 45.0-51.0 |

| Weight (with product) | [t] | 6.53-7.95 | 14.2-23.6 | 35.3-39.9 | 48.5-56.5 |

All technical data are approximate and subject to change without notice.

Krauss-Maffei pressure drum filter TDF outline