Applications

Gas stripping, distillation, liquid-liquid reactions, degassing, nanoparticles

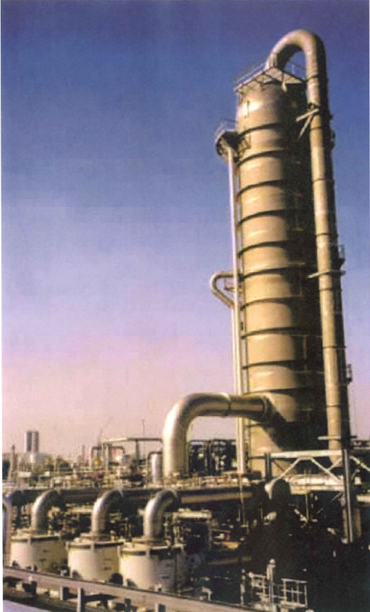

The ANDRITZ rotating packed-bed centrifuge uses the HiGee technology and provides a quantum leap in terms of process intensification for gas stripping, distillation, as well as liquid-liquid reactions. With the ANDRITZ RPB technology, traditionally column-based processes can be designed to be considerably more compact, while yield and quality are increased.

The HiGee technology (high-gravity) utilizes centrifugal forces to overcome the limitations of traditional packed columns and at the same time reveals unique process features. A major advantage of this technology is the greatly increased mass transfer rate as well as the enhanced micro-mixing. Reactions with limited dwell time as well as extremely fast reactions can be maintained under controlled conditions easily inside the RPB centrifuge. Additional advantages are the smaller dimensions of the unit, which lead to lower capital, installation, and operating costs. Completely new fields of application are opened up with this technology, such as mobile plants, high-pressure plants, and processing of viscous media. Industrially proven examples of the application of RPB technology are the production process for hypochlorous acid, or absorption processes like SO2 or H2S removal. ANDRITZ Separation has designed and delivered the world’s largest RPB installation – a set of four RPBs for DOW Chemicals.

Highest conversion yields, optimized mass transfer rates, due to:

Fewer by-products due to:

Reduction of capital and operating costs because of:

Completely new applications possible, such as:

The efficiency of the RPB reaction is increased by between 20 and 100 times compared to traditional packings.

Gas stripping, distillation, liquid-liquid reactions, degassing, nanoparticles

The rotating packed bed centrifuge utilizes centrifugal force (HiGee) to increase the mass transfer rate within the packing. Due to the increased g-force, the liquid film in the packing is drastically reduced, which provides several unique features in RPB technology. The packing density as well as the gas volume flow through the packing can be increased without any greater risk of flooding or larger pressure drop. Both ensure that the RPBs can be built with a higher specific reaction surface per m³ of packing. The efficiency of the reaction is thereby increased by between 20 and 100 times compared to traditional packings. Moreover, the thin, turbulent liquid films show optimized micro-mixing that is up to 2-3 magnitudes better than in dedicated mixing tanks. These features enable the RPB technology to also handle extremely fast liquid-liquid reactions, which are typically difficult to control because the reaction has already finished before the reactants have been mixed homogenously. The fast-reaction kinetics in the rotating packing lead to very short retention times of the liquid and gas phases inside the machine.

A major advantage of this is the avoidance of by-products, which are produced according the dwell time of the reactants in the packing. If these by-products are critical in the downstream process, the RPB is the right solution to the problem.

ANDRITZ is your reliable partner for the development of fast-rotating equipment like RPBs. Due to our many years of experience in building centrifuges and filters, we can offer RPBs with approved mechanical components. Minimum downtimes for maintenance and no unexpected maintenance stops will improve the performance of your plant. We offer custom-designed industrial units as well as small-scale test units for process development.