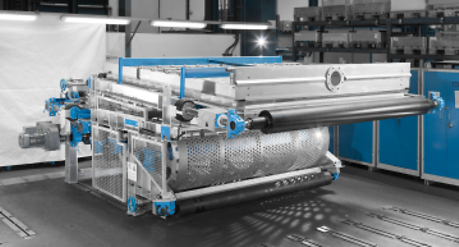

A new standard in flexible, efficient and high-throughput dewatering with ANDRITZ belt press CPF-Q

The ANDRITZ belt press CPF-Q is a continuously operating, heavy-duty belt filter press manufactured in a modular design with unique flexibility. In fact, we have been working closely with customers for more than 150 years to continuously improve the lifetime value of every machine. Our latest heavy-duty belt press is part of this evolution, setting a new standard in throughput, efficiency, and reliability.

The ANDRITZ belt press CPF-Q delivers lower residual moisture, higher throughput, and is more flexible to changing feed conditions than any other belt press on the market.

The ANDRITZ belt press CPF-Q has been developed in close cooperation with our customers in order to address the key challenges in modern dewatering and filtration. Despite its small footprint, the robust design contains an impressive array of features, including a reliable belt tension system and a flexible drive (hydraulic or electric). Compared with conventional belt presses, the cost of ownership is minimal, remote service is simple, and a greatly extended lifetime of high availability makes the machine reliable, simple, and cost efficient to operate.

Your benefits

- Highest throughputs of up to 50% more than comparable competitor machines

- Lowest required residual moisture of final product

- Optimized flocculant consumption (e.g. with RheoScan system)

- Reliable non-stop operation and highest availability

- Flexible operating parameters (e.g. belt speed and belt tension as well as filtration pressures can be adjusted acc. to process requirements)

- Modular design, small footprint, and easy to access and maintain

Applications

- Tailings from the mining and coal industries

- Contaminated soil

- Harbour sludge

- Dredgings

- Oxalate in alumina refineries

- Various industrial sludges

- Cooking slurry

- Various other chemical applications

- Residue from quarries

- Citric acid