Applications

Dewatering applications

- General tailings

- Gypsum

- Phosphate rock

- Coal fines

- Magnetite

- Iron ore

- Lithium

Washing applications

Leached materials

Zinc

Copper/cobalt

Nickel

Gypsum

Flue gas desulfurization (FGD)

Pulp washers

In the most challenging applications, for example chemicals or mining and minerals, reliable dewatering and product recovery is critical to maintaining continuous production. This is why ANDRITZ has put decades of expertise into the Horizontal Vacuum Belt Filter (HVBF) technology, to provide a solution with the highest throughput and low residual cake moisture content, while keeping operating costs low.

The horizontal vacuum belt filters by ANDRITZ offer numerous advantages for process plants:

High-throughput dewatering and cake washing

Reduced downtime due to innovative design

Global testing facilities

Increased flexibility due to modular design

Largest belt filter plant in the world consisting of 26 HVBF units each with 80 m² filter area

© ANDRITZ20m² horizontal vacuum belt filter installed in a graphite concentrate dewatering application

© ANDRITZANDRITZ has fully integrated engineering capabilities that enable accurate design with state-of-the-art technology to provide optimized equipment sizing and footprint.

Engineering capabilities include:

The wide variety of materials of construction and the bolted frame structure allow for modular designs that are customized to the clients‘ requirements.

High extraction efficiencies are the key to profitability in most washing applications, whether it is for gold, uranium, phosphoric acid, copper, or alumina. The horizontal vacuum belt filter can attain wash efficiencies of more than 99.8% as plug flow displacement and multi-stage counter-current washing is utilized over the filtration area.

We offer a complete range of solutions for corrosive, abrasive and hot filtering applications; from the highest quality stainless steels to FRPs and plastics. The filter frames are manufactured from open channel and angle sections to prevent problems associated with corrosion when using box sections.

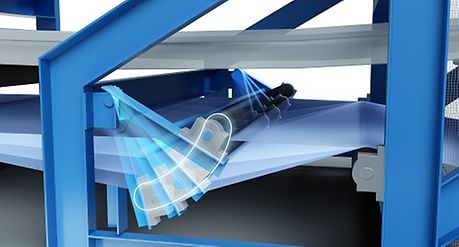

Cake discharge on most applications is spontaneous, but ANDRITZ makes use of cake scrapers or water slides to ensure complete cake removal in the event of wet, sticky products. In addition, ANDRITZ has constructed the widest filters using 4.8 m rubber belts (available in natural rubber, SBR, neoprene, and EPDM, depending on the process requirements). All ANDRITZ transporter belts have a carcass-free center zone to ensure long life by preventing contact between the carcass and corrosive filtrates.

Typical cake discharge on a horizontal vacuum belt filter

© ANDRITZANDRITZ has developed a new device for lifting vacuum boxes on horizontal vacuum belt filters – the SmartLIFT. Not only does the device make short work of a classically high-risk task, it can also be retrofitted to any brand or size and reduces downtime for vacuum box maintenance by over 30%. Find out more:

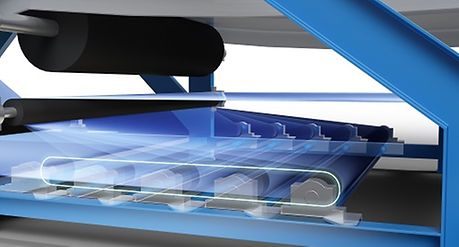

The ANDRITZ filters are designed with a dual cloth tensioning system (static and dynamic). This allows the filters to continue operating efficiently even if the cloth stretches abnormally and also allows for easy installation of the filter cloth due to movable rollers.

HVBF Static cloth tensioning system

© ANDRITZHVBF Dynamic cloth tensioning system

© ANDRITZLeached materials

Zinc

Copper/cobalt

Nickel

Gypsum

Flue gas desulfurization (FGD)

Pulp washers