ANDRITZ Soutec AG, Switzerland

Rotfarb 4

8413 Neftenbach

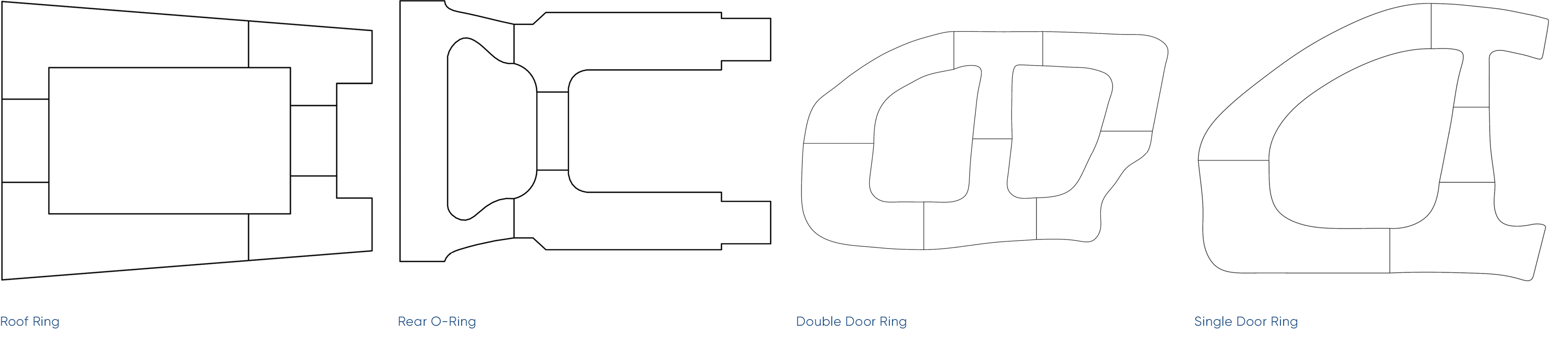

SOUFLEX is the answer to the strong growth of large laser welded Tailored Blanks such as Door-Rings, H-Frames, O-Frames, Sun-Roofs, and other so called “Multi Part Integration“ or “Large Tailored Components“ applications and solutions. Designed for maximum flexibility, efficiency, reliability at almost no tool and fixture cost, this cutting-edge technology ensures seamless integration into modern production environments. With various options in regard of automation degree and weld process technologies, SOUFLEX unlocks new possibilities in manufacturing with a solution that combines productivity, accuracy, and highest quality.

SOUFLEX enables reduced investment and lower piece cost through:

| Parameter | Value |

| Blank dimension | max. area: 3,000 x 1,800 mm |

| Blank thickness | 0.8 – 2.5 mm |

| Seam length | Typical seam length: 150–500 mm* *other dimensions on request |

| Number of seams | max. 14 seams (deviation optional) |

| Weldable Materials | AlSi coated Zn coated for direct/indirect hot form process All AHSS material |

| USP | |

| SOUPOS | adjust blank to target position |

| SOUFIL | dynamic and accurate filler wire feeding system |

| SOUGAP | beam shaping technology for up to 0.5mm gap closing |

| SOUVIS 6200AI | AI-powered Quality Control system, combining 2D gray-level imaging and 3D scan data for superior reliability |

| SOUBLOG T&T | Track & Trace data storage, full traceability, detailed reporting |

| Options | |

| SOUFLEX-AB | In-line ablation module (compact line) |

| SOUFLEX-ABM | Ablation module prior welding unit (highest productivity) |

| Manual loading | No automation (customizable) |

| Tailored blank type / seam type | Complex linear applications Alternative applications on request |