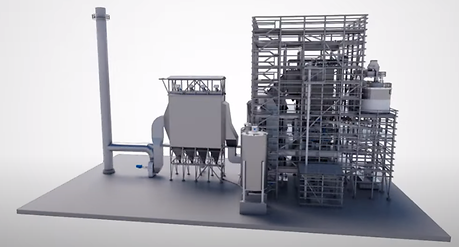

Scalable and reliable

Whether your plant requires a compact solution or a large-scale installation, EcoFluid boilers adapt to your requirements. Available in top- or bottom-supported configurations, they feature modular components for fast construction and easy scalability. Every heating surface is tailored to your process, ensuring maximum efficiency. Built with robust materials and conservative design principles, EcoFluid guarantees high availability and low maintenance—keeping your operations running at peak performance.

- Top- or bottom-supported configurations to suit any capacity and site conditions

- Modular components for fast installation and easy scalability

- Tailored heating surface arrangement for customer-specific requirements

- Conservative material selection ensures high plant availability and low maintenance